I still remember a winter annual on a well-loved 172 where the owner swore “it’s flown fine for years.” Thirty minutes into the inspection we found a hidden lap-joint corrosion patch that would’ve turned a routine cross-country into a very bad day. That’s maintenance in a nutshell: when you do it right, nothing dramatic happens—and that quiet, uneventful result is exactly what we’re paid to deliver.

This guide is the version I hand to new owners, flight-school managers, and junior techs. It’s practical, it’s straight from the hangar floor, and it’ll keep you on the right side of the regs and the runway.

What “maintenance” actually means—and who can touch the airplane

If you’ve ever argued over whether a task is “maintenance” or “preventive,” you’re not alone. Under 14 CFR Part 43, maintenance includes inspection, repair, preservation, and part replacement; certificated A&Ps and Part 145 repair stations do the heavy lifting, and only certain preventive maintenance items belong to pilots. When I mentor owners, I point them to the primary source and we mark what they can legally do (spark plugs, wheel bearings, safety wire) versus what they should leave to us. Read the rule here and bookmark it: 14 CFR Part 43 – Maintenance, Preventive Maintenance, Rebuilding, and Alteration.

(Pro tip from years of logbook audits: if you do a pilot-permitted task, write the entry like a pro—clear description, date, tach/TT, and your signature with certificate number. A crisp log entry is cheap insurance at resale.)

When you want a plain-English walkthrough of owner tasks, check our step-by-step primers in Flight School Guides and the budgeting worksheets in Pilot Career Advice—they’re set up so you can print and take them to the hangar.

Required inspections for Part 91 (my GA cheat sheet that actually works)

- Annual (every 12 calendar months): IA sign-off required. I schedule these so the post-maintenance acceptance flight lands before month-end; it keeps surprises out of holiday weekends.

- 100-hour (when carrying persons for hire or giving instruction for hire in that aircraft): A&P sign-off allowed. If you’re “over,” you can reposition to a shop, but don’t make a habit of it.

- Progressive programs: If you run a school or busy club, FSDO-approved progressive phases keep airplanes flying while inspections roll through the fleet.

- IFR checks: Altimeter/static/encoder under §91.411 and transponder under §91.413 every 24 months, ELT under §91.207 per battery/inspection schedule. I align 24-month checks with annuals to minimize downtime and paperwork whiplash.

For owner-operators, we keep printable calendars and “parts-lead” trackers in Pilot Career Advice—use them, and you’ll beat 90% of the avoidable delays.

Airlines & charter in one paragraph (so you know what the pros do)

Parts 121/135 live inside CAMP with reliability programs and MRB-derived task cards. Work is batched in A/B/C/D-style packages (the labels vary, the discipline doesn’t). The relevant lesson for GA: build your own mini-CAMP—recurring tasks list, AD status sheet, logbook indexing. If you fly turbines or cabin-class pistons, our platform rundowns in Private & Business Aircraft show what “big-iron discipline” looks like at owner scale.

MEL vs. KOEL vs. MMEL (how to dispatch legally without playing roulette)

Your AFM/POH’s KOEL tells you what must be working for Day/Night and VFR/IFR. If your type has an MMEL, you (or your operator) can build an MEL that legally defers specific inoperative items with placards/procedures/repair intervals under §91.213. I’ve seen too many pilots treat a MEL like a permission slip—remember, it’s a procedure, not a hall pass. For the FAA’s plain-language refresher and the policy links I send to new chiefs: FAA MEL/MMEL Overview.

From my experience, a laminated “Day VFR / Night VFR / IFR” KOEL card on the yoke and a neat MEL binder in the seat pocket will cut your pre-taxi debates in half.

ADs vs. SBs (and the log that saves you at pre-buy)

Airworthiness Directives (ADs) are mandatory—they correct unsafe conditions and carry the weight of law. Service Bulletins (SBs) are OEM recommendations; they often make sense, and sometimes an AD later incorporates them. Keep a dedicated AD sheet listing AD number, subject, method of compliance, and next due across airframe, engine, prop, and appliances. I build AD logs once and update them every annual—buyers love it, and it keeps you from missing recurring actions. Start your searches here: FAA Airworthiness Directives Portal.

The technical data your mechanic actually uses

When we sign your airplane off, we’re leaning on approved/acceptable data: AMM, IPC, SRM, WDM, SBs/SLs, and sometimes DER-approved repairs. Ask us to cite chapter/task in the log for complex work; keep copies of referenced pages in your records. Six months later, when a new tech is troubleshooting that intermittent alternator trip, those notes save hours.

Writing logbooks and return-to-service entries (so an IA doesn’t kick them back)

Two anchors: §43.9 (maintenance/alterations) and §43.11 (inspections). Entries must include a clear description, reference to data used, date, TIS/TT as applicable, and the signature/certificate number of the person approving (or not approving) for return to service. Failed inspections require a discrepancy list. Before you pull the chocks, read the entry against 43.9/43.11. If something’s missing, fix it now.

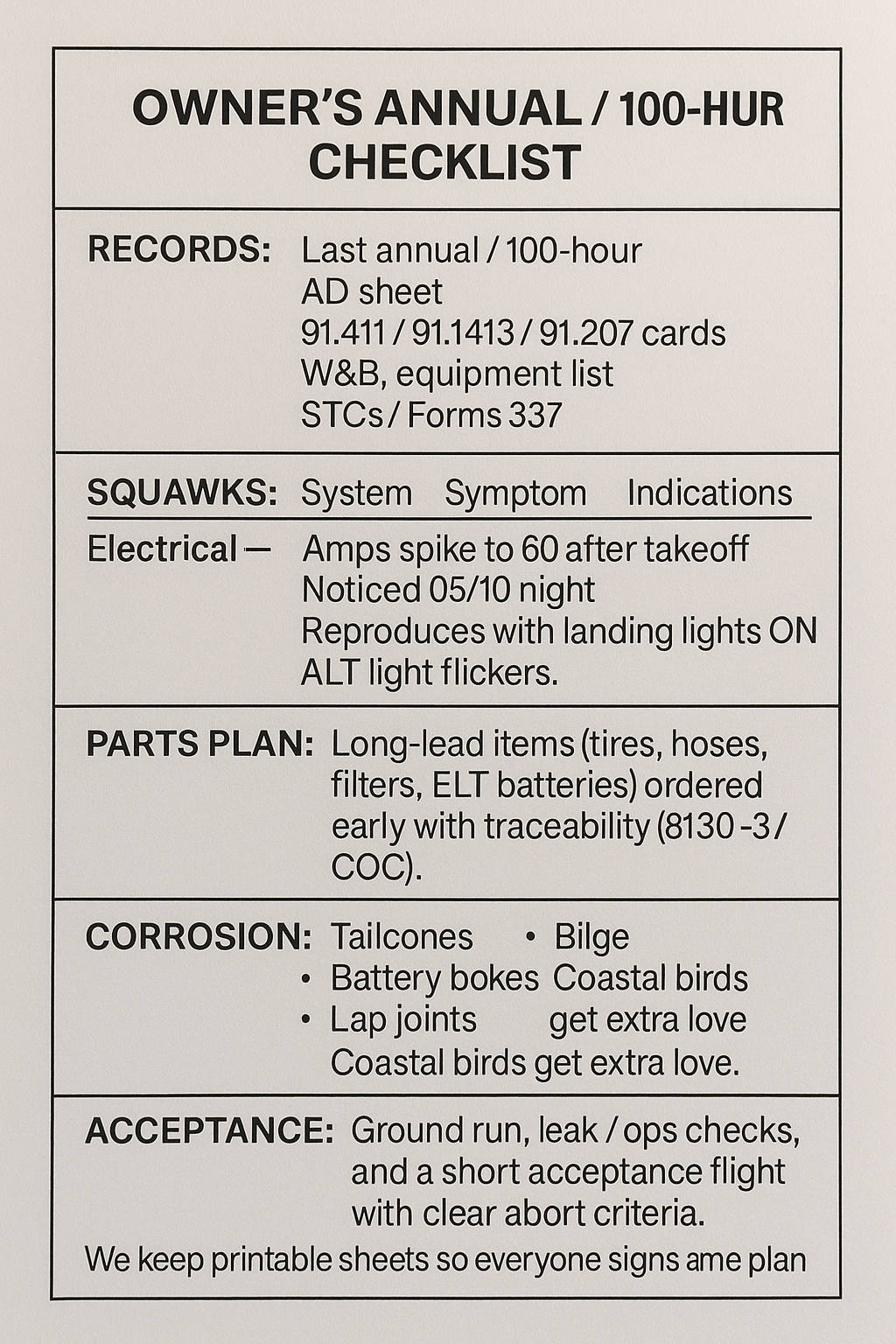

The owner’s annual/100-hour checklist I use in real life

- Records: Last annual/100-hour, AD sheet, 91.411/91.413/91.207 cards, W&B, equipment list, STCs/Forms 337.

- Squawks: Use a precise template—System / Symptom / When / Repro / Indications. (“Electrical—Amps spike to 60 after takeoff—noticed 05/10 night—reproduces with landing lights ON—ALT light flickers.”)

- Parts plan: Long-lead items (tires, hoses, filters, ELT batteries) ordered early with traceability (8130-3/COC).

- Corrosion: Tailcones, battery boxes, lap joints, bilge. Coastal birds get extra love.

- Acceptance: Ground run, leak/ops checks, and a short acceptance flight with clear abort criteria. We keep printable sheets in Pilot Career Advice so everyone signs the same plan.

How pilots and mechanics collaborate (and save each other time)

A precise squawk can turn a three-hour Easter-egg hunt into a 45-minute fix. You write it clearly, we translate it into the AMM/WDM flow, correct the fault, and reference the data and any AD/SB in the entry. Then we verify on a controlled run-up and, if needed, a short hop. Keep a shared squawk log; repeat offenders jump off the page.

From my experience, a five-minute face-to-face at drop-off—where you show photos, reproduce a sound, or point to a leak stain—saves a day of phone tag.

Common compliance traps (and my fixes)

- Missed AD intervals: Live AD spreadsheet with Next Due and a calendar tickler.

- IFR check drift: Align 91.411/91.413 with the annual; set reminders in three calendars (yours, your IA’s, your scheduler’s).

- Parts traceability gaps: Ask for 8130-3/COC where required; staple supplier invoices to the work order.

- Weak log entries: Verify 43.9/43.11 elements before you accept the airplane.

- W&B drift: Demand updated weight & balance and equipment list after avionics/interior changes.

- Torque/seal details: Photograph brake lines, prop safety wire, torque paint—drop photos into the digital file.

If you want acceptance checklists you can hand to a new hire, we’ve packaged our templates inside Flight School Guides—it’s the same kit I give fresh dispatchers.

Tooling, test equipment, and calibration (trust but verify)

Accuracy rides on calibrated tools: torque wrenches, pressure gauges, micrometers, pitot-static testers, ignition analyzers. After your 24-month IFR checks, get copies of the altimeter/static report and transponder bench card; file them with the logs. Vetting a shop? Confirm ratings and capabilities in the FAA’s DRS before you drop off the keys.

When to bring in a specialist

Structural repairs, composite layups, complex avionics integrations, and prop governors belong with shops that have the jigs and repairman authorizations. Chronic gremlins—high CHT, intermittent alternator trips, autopilot oscillations—often yield in a day at an OEM center or a strong 145 with type experience.

If you need the FAA’s primer on special ferry flights to reposition for heavy work, keep this handy: FAA – Special Flight Permits.

A fictional—but real-world—case: the 100-hour that saved a season

Flight school, three Archers, summer rush. Airplane 2 keeps blowing the ALT FIELD breaker on climb-out; three different squawks say “intermittent.” We built a clean write-up (System/Symptom/When/Repro/Indications), found a chafed wire at a clamp behind the panel, and—here’s the human part—discovered the clamp had been re-used with a slightly undersized cushion two avionics upgrades ago. We replaced the clamp, rerouted the harness per WDM guidance, added torque paint, and photographed the fix for the digital file. Downtime: 0.6 day. Avoided parts: one alternator, one voltage regulator, two “shotgun” hours. That 100-hour paid for itself before lunch.

FAQs I keep getting (U.S., 2025)

What can a private pilot legally do? Only items in Part 43 Appendix A(c), with a proper log entry it’s on you to write.

A&P vs. IA? A&P performs maintenance; an IA performs and approves annuals/majors and signs Form 337 for major repairs/alterations.

Are SBs mandatory? Not unless pulled into an AD or required by your program/lease/warranty.

Can I fly to a shop with an expired annual? Yes—with a special flight permit if the airplane is safe for that flight (see the FAA link above).

How do I know which ADs apply? Search the FAA AD portal by airframe/engine/prop/appliances and keep a signed compliance list on file.

If you want the FAA’s one-stop page that ties KOEL/MEL/MMEL policy together for a dispatcher or new chief pilot, this is the one I share: MEL/MMEL—FAA Policy & Guidance.

Keep leveling up with Aviation Titans

We’ve bundled owner workflows and checklists in Flight School Guides, built sim-drills for post-maintenance acceptance flights inside Simulator Technology, and compared platform-specific maintenance realities in Private & Business Aircraft. When rules change (new AD notes, inspection guidance), we post the “so what” for operators in our news stream.

Bottom line

Staying safe and compliant in 2025 is about habits as much as hardware: know your lanes under Part 43, keep your records tight under 43.9/43.11, run a living AD/SB sheet, and collaborate with your mechanic using precise squawks and pre-agreed acceptance criteria. The payoff is measurable—fewer surprises, faster turns, cleaner pre-buys, higher resale—and, most importantly, an airplane you trust every time you advance the throttle.

Owner’s bookmark for rainy Saturdays: when you’re researching ADs or building a model-specific deferral policy, start at the FAA’s official pages instead of a forum thread: FAA Airworthiness Directives Portal. And if you need a refresher on what you can legally defer (MEL) versus what you must fix (KOEL/91.213), the FAA’s summary is here: MEL/MMEL Overview.