I’ve been around long enough to remember when seniority lists barely moved and upgrades felt like a mirage. That changed fast. Over the past few years I’ve watched classes of senior captains finalize retirement dates, maintenance leads hand over toolboxes, and cabin managers train their replacements. The scale is different now. Boeing’s long-range outlook projects nearly 2.4 million new aviation professionals by 2044—about 660,000 pilots, 710,000 maintenance technicians, and more than a million cabin crew. If you’re wondering whether there’s room for you in this industry, the short answer is yes; the real question is where you’ll create the most value and how quickly you can get competent.

This isn’t academic. I’ve sat in upgrade boards where the tie-breakers came down to a candidate’s ability to brief a non-precision approach cleanly or to explain an MEL deferral without hand-waving. In MRO shops I’ve seen new hires go from tentative to indispensable once they understood composite scarf repairs and how to interpret health-monitoring trends. The jobs are there. Your task is to match what you bring with where demand is spiking—and to train in a way that shortens your runway to proficiency.

Why the workforce is expanding—even with smarter airplanes

Retirements are the biggest driver. The cohorts hired in the late 1980s and 1990s are timing out, and that’s creating backfills across cockpits, hangars, and cabins. When my old airline published a retirement forecast, we could plot captain upgrades 18 months ahead with startling accuracy. That visibility translated into aggressive recruiting and earlier type-rating commitments for internal candidates.

Fleet growth matters too. Orderbooks are still stacked, airlines are swapping older jets for more efficient types, and long-range single-aisles are rewriting route economics. Every delivery means additional line checks, more maintenance hours, and fuller crew rosters. I once tracked a base where the addition of two narrow-bodies translated into six captain upgrades, eight first-officer hires, and three extra line maintenance slots—before we even talked about vacation relief.

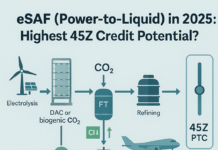

Technology is changing the work, not eliminating it. Predictive maintenance doesn’t fire an AMT; it gives that AMT a higher-leverage job. Pilots spend less time heads-down and more time managing edges: weather, fuel strategy, terrain, and automation surprises. Cabin crew juggle more complex service standards alongside safety and medical readiness. That’s why the quality of training—not just the hours—has become the differentiator.

If you want the twenty-year numbers from the source, Boeing’s public summary of the Pilot & Technician Outlook remains the industry’s baseline reference, and it’s worth a careful read for regional breakouts and methodology. See the current summary here: Boeing Pilot & Technician Outlook.

The global picture, translated for job seekers

The regions with the strongest projected hiring—Eurasia/Europe, North America, China, Southeast Asia, and the Middle East—aren’t recruiting in isolation. I’ve watched U.S. carriers lose instructors to Middle East wide-body fleets offering quicker upgrade clocks, and I’ve seen Southeast Asian LCCs pull in technicians with composite experience faster than local shops can train them. Expect compensation to chase scarcity, not just seniority.

When I spoke with a regional airline recruiter this summer, she mentioned a roughly 30% increase in applications to their accelerated cadet track compared to last year, but here’s the detail that matters: simulator seat availability capped actual class starts. That’s the story everywhere. The bottleneck isn’t interest; it’s throughput.

What this means for you, role by role

Pilots: use competencies to beat the hour race

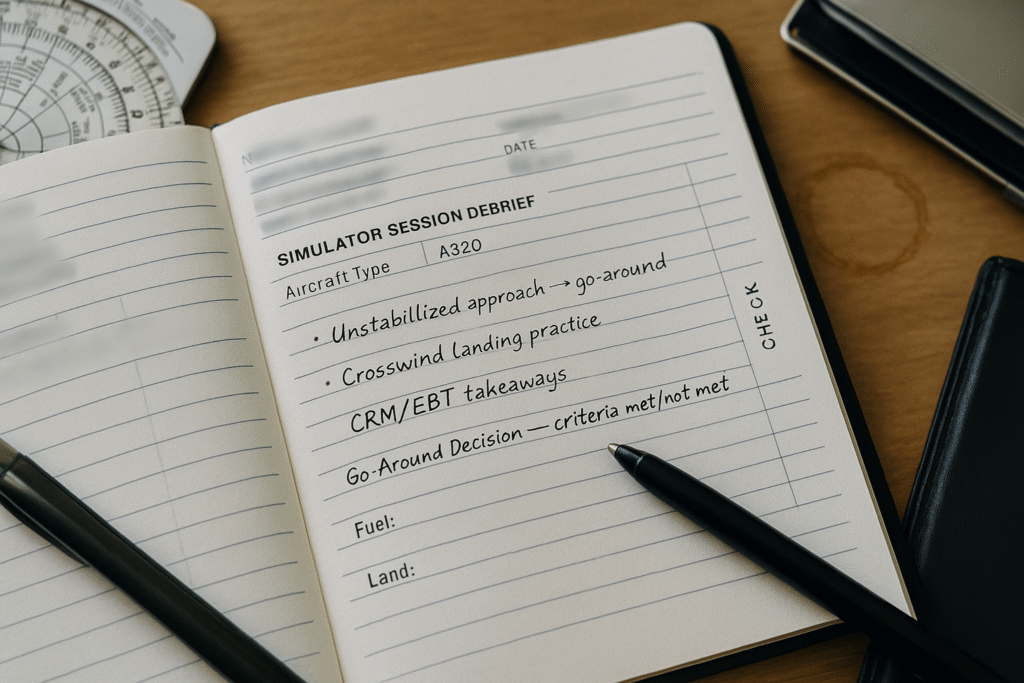

If you’re chasing the right seat, don’t just stack hours—stack competencies. Hiring panels can tell who’s been taught to think in evidence-based training (EBT) terms: threat assessment, error traps, stabilized approaches, and disciplined go-around criteria. The candidates who advance are the ones who can articulate a decision chain, not just recite flows.

From my experience, a clean training record and a handful of crisp, quantified stories will do more for you than a messy logbook with an extra hundred hours. One FO I mentored landed his upgrade after walking the panel through a real diversion decision where he balanced runway condition codes against a trending crosswind and a marginal ceiling. He didn’t grandstand; he simply showed his math.

If you’re still deciding how to structure your licenses, ratings, and budget—and whether to choose a Part 61 or 141 program—this primer will save you time: How to Choose a Flight School in 2025: Part 61 vs Part 141, Syllabus, and Costs.

AMTs and avionics technicians: where the shortage is biting

In North America in particular, the maintenance pipeline isn’t filling as quickly as positions open. The Aviation Technician Education Council has been warning about this for years, and if you’re on the fence about an A&P or an avionics track, their pipeline snapshots are clarifying: ATEC Pipeline Report.

What I’ve learned is that the combination of composite repair skills, strong electrical troubleshooting, and comfort with digital dashboards (condition-based maintenance, borescope analytics, data log parsing) puts you on the short list quickly. A mistake I see a lot of new techs make is treating the manual as a script rather than a system. The best techs diagnose, not just replace.

Cabin crew: where service and safety intersect

Don’t let the smiles fool you—this is a high-discipline role. Medical readiness, security awareness, and CRM are as central as service choreography. Multilingual skills and documented service recovery wins carry weight. I’ve seen crew land premium-cabin bids because they could explain, with receipts, how they turned a delay into a top-quartile NPS recovery flight.

New frontiers: AAM/UAM

Early electric and powered-lift operators need people who can bridge airline-style SOPs with new energy systems. If you’re the kind of person who enjoys both checklists and bleeding-edge tech, this is your playground. Start with the regulatory workstreams so you’re not guessing about certification and integration: FAA — Advanced Air Mobility.

A maintenance case study you can learn from

A few winters back, our line team flagged an intermittent vibration report on a long-range composite wing panel after moderate turbulence. On walk-around, you wouldn’t have noticed much—just a scuffed area near a fastener line. The pilot write-up was vague: “buzz” at certain speeds. We pulled historical data from the aircraft health monitoring system and saw a small but repeatable spike in strain-sensor readings near the mid-span. Tap-test gave a dull response over a 6×8 cm ellipse; UT confirmed a disbond between the skin and a sub-stringer cap.

Here’s how we resolved it:

- Controlled strip and scarf. We mapped the damage to the SRM, then executed a scarf repair with a 20:1 taper. The prep alone took most of the shift—any contamination at this step haunts you later.

- Ply schedule. We rebuilt with a stepped layup, alternating fiber orientation per spec. We documented each ply placement and roll-out pressures; a new tech shadowed me and learned how to chase air at the edges.

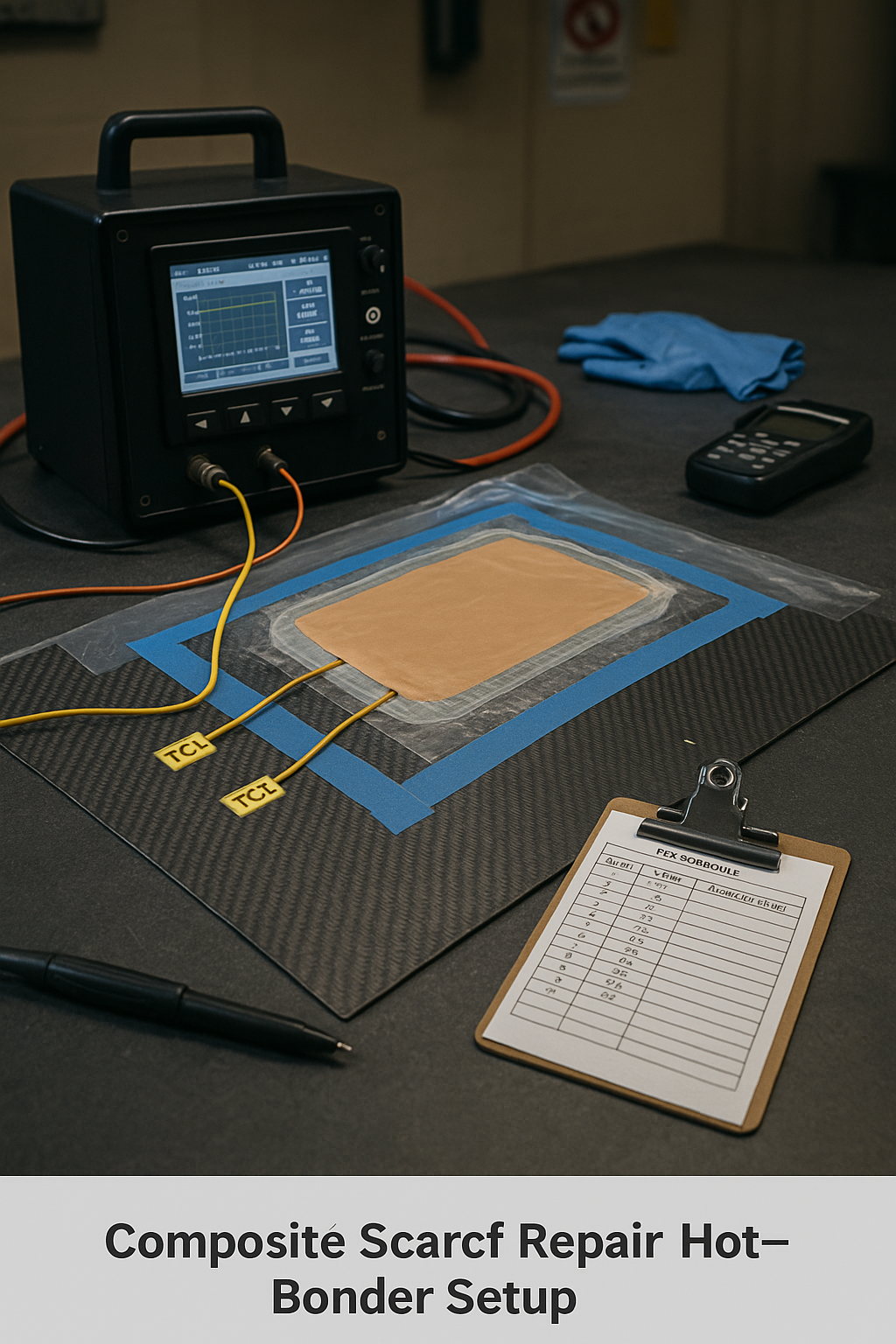

- Cure cycle. We used a portable hot-bonder with two thermocouples in the bondline and one as a control, stepped the cure per the resin system, and kept a hawk’s eye on ramp rates.

- Post-cure inspection. UT and a tight tap map showed a uniform response; a borescope check through a nearby access panel confirmed no witness marks on the sub-structure.

- Paperwork and follow-up. We logged the repair depth, ply schedule, cure profile, and NDT results. On the next flight cycle, we trended the sensor output—no spike.

That job turned a nervous new hire into a confident composite tech. More importantly, it reminded the team that “predictive maintenance” isn’t an algorithm replacing judgment; it’s a cue for a human expert to go look exactly where the airplane is whispering.

Training is the bottleneck—and the opportunity

Throughput limits are real: sim hours, instructor availability, check airman bandwidth. I’ve seen airlines solve this by standing up cadet pipelines and by poaching experienced instructors with better schedules. For technicians, registered apprenticeships shrink the time from classroom to signed-off tasks, which is where your confidence really builds.

If you want a macro view of why cargo continues to prop up demand for both pilots and AMTs—night ops, high utilization, specialized handling—keep an eye on monthly market readouts: IATA — Economics & Air C<argo Market Analysis.

From my experience, the fastest learners keep a personal training portfolio. After every sim or check, write two paragraphs: what you planned, what actually happened, what you’ll do differently. Do the same after a tough maintenance shift: fault tree, tests performed, root cause, corrective action. It sounds simple; few people do it.

Picking a path that leads to a real job

For pilots, start with a sober budget from PPL to CFI/CFII and don’t forget fuel and examiner buffers. If your region is A320/B737 heavy, concentrate your chair-flying and flows accordingly. Practice LOFT-style scenarios, not just maneuvers: unstabilized approach calls, diversion briefs, crosswind landings on wet runways with gusts. When it’s interview time, bring concrete stories with numbers and lessons learned.

For technicians, credentials open the door and specializations get you the shift you want. Avionics, borescope and NDT, composite repairs, and high-voltage safety for hybrid/electric platforms are all paying off. Capture your work with before/after photos where permitted and track metrics like repeat snag reduction or MTBUR improvements. Hiring managers notice.

If you’re mapping the big picture and want a single place to start, I keep pointing newcomers to a plain-English breakdown of where the 2.4 million number lands and why the demand is structural: Aviation Jobs Forecast 2044 — What It Means for Your Career.

Recruiting is changing; use it to your advantage

Cadet programs and direct-entry pathways are compressing the journey to the right seat. On the maintenance side, paid apprenticeships let career-changers prove themselves without going broke. Universities and airlines are signing MOUs that guarantee interviews if you hit specific milestones. Assessment days are different too—expect group problem-solving around realistic scenarios, not just a written quiz.

What I’ve learned is that a one-page “achievement brief” beats a bloated resume. Three bullets for safety, three for technical mastery, three for customer impact. Make them measurable: “Cut repeat write-ups 18% by standardizing borescope checklists and adding photo confirmation to sign-offs.”

Standards during a hiring surge: yes, they’re holding

Rapid hiring spooks people who worry about diluted standards. The counterweight is robust: CRM training, human factors, and evidence-based checks. On the line, I’ve watched captains decline approaches that met the letter but not the spirit of stabilized criteria—and their chief pilots backed them. In the hangar, I’ve seen QA teams push back on schedule pressure to re-run an NDT procedure when the data looked off. That’s the culture you want to join.

If you’re gravitating toward instruction, mentor roles, or safety management, there’s a lot of opportunity to shape that culture. I’ve never seen such a wide open lane for people who can teach well and think clearly under pressure.

Humans + automation: how the work actually shifts

Will automation replace pilots and technicians? I doubt it. What changes is where humans spend their time. Pilots will handle more exceptions, fewer rote tasks. Techs will interpret more data, perform fewer blind part swaps. Cabin crew will spend more energy on service recovery and medical readiness as cabins densify and premium products multiply. If you enjoy solving higher-order problems and you’re willing to keep learning, you’ll do well for decades.

The bottom line

By 2044, airlines, MROs, cargo operators, and corporate flight departments will need a staggering number of skilled people. The opportunity is real, and the path is clearer than it’s been in a long time. Your edge won’t be a secret handshake; it’ll be competence you can demonstrate. Build it methodically, document it, and communicate it well. The hiring wave is underway—ride it with purpose.

If you want a practical, step-by-step roadmap—ratings, sim prep, and interview strategies that reflect what panels are actually asking—start here and bookmark it for later: Pilot Career Advice — How to Overcome First Solo Flight Fear (CFI-Backed Advice).

FAQs

How risky is it to start flight training now, given costs?

It’s not risk-free, but the multi-year hiring window driven by retirements and fleet growth is still favorable. Reduce risk by picking programs with strong placement records, realistic timelines, and access to modern sims. Track your costs weekly and brief your plan like you would a flight.

Can an automotive or IT technician pivot into avionics?

Yes. Your diagnostic mindset transfers. Close the gaps on regulatory paperwork, safety culture, and system-specific training. Ask for projects that let you practice methodical fault isolation. Document your results.

What gives pilots a competitive edge beyond hours?

Clear decision-making stories, evidence-based training habits, and a clean record. Be the person who knows when to go around and can explain why without ego.

Which maintenance specializations are paying off fastest?

Avionics, NDT/borescope, composite repair, and high-voltage safety for hybrid/electric systems. Add a type course or OEM module when you can; it pays back in shift preference and bid success.

Will cabin crew demand hold if airlines deploy bigger aircraft?

It will. Bigger cabins and denser schedules don’t reduce the need for qualified crew; they increase the premium on medical readiness, language skills, and service recovery.

Sources and further reading

For the twenty-year personnel outlook, see Boeing’s summary: Boeing Pilot & Technician Outlook.

For the maintenance pipeline context, the ATEC brief is handy: ATEC Pipeline Report.

For AAM regulatory integration, start with the FAA’s overview: FAA — Advanced Air Mobility.

For monthly macro trends in freight and economics, I keep an eye on: IATA — Economics & Air Cargo Market Analysis.