A Day in the Life: The Technician Who Sees What Others Can’t

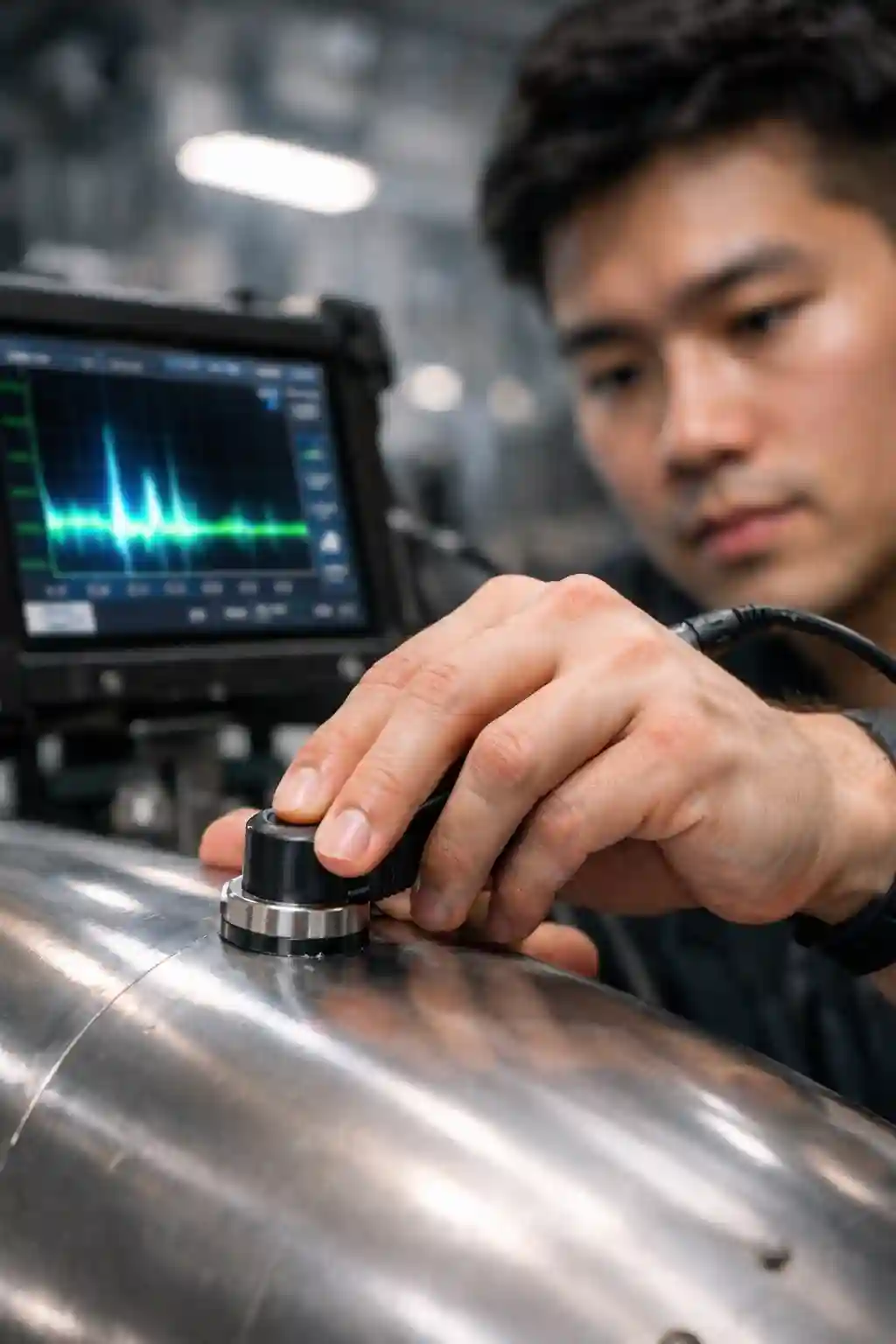

It’s 6:47 a.m. at SpaceX’s Hawthorne facility, and 24-year-old Marcus Chen is doing something that looks straight out of a sci-fi movie. He’s running an ultrasonic transducer across a titanium rocket component, watching sound waves bounce back on his screen in real-time. One anomaly—a microscopic crack invisible to the naked eye—could mean the difference between a successful launch and catastrophic failure.

Marcus isn’t a software engineer. He didn’t go to a four-year university. Six months ago, he was working retail at Best Buy, drowning in $35,000 of student loan debt from two years of community college he never finished. Today, he’s pulling $52,000 as an NDT Level I Technician, with a clear path to six figures within five years.

“People think I’m joking when I tell them I use X-rays and ultrasound at work,” Marcus laughs during his lunch break. “My friends from high school who got their bachelor’s degrees? Half of them are unemployed or making $40k doing data entry that ChatGPT will probably replace next year.”

He’s not wrong. And he’s part of a quiet revolution happening in American aviation—one that’s rewriting the rules about what “blue-collar” really means in 2026.

The White-Collar Crisis No One’s Talking About

Let’s talk about the elephant in the room: the traditional path is broken.

American students now collectively owe $1.77 trillion in student loan debt, according to recent data from the Federal Reserve. The average bachelor’s degree holder graduates with $30,000 in debt and faces an entry-level job market increasingly dominated by AI automation. Marketing coordinators? Replaced by AI content generators. Junior analysts? Automated by machine learning algorithms. Even entry-level software developers are feeling the squeeze as AI coding assistants become more sophisticated.

Meanwhile, the aviation industry is facing a technician shortage crisis. The Federal Aviation Administration projects that commercial aviation alone will need over 690,000 new technicians globally by 2030. But here’s the kicker: these aren’t jobs that can be automated away. You can’t ask ChatGPT to physically inspect a turbine blade for fatigue cracks.

Enter Non-Destructive Testing (NDT)—the career path hiding in plain sight.

What is NDT? The Science of Seeing the Invisible

Non-Destructive Testing is exactly what it sounds like: inspecting materials and components for defects without destroying them. In aviation, NDT technicians are essentially the doctors of aircraft—using advanced technology to diagnose problems before they become catastrophic.

Think of it this way: when you get an X-ray for a broken bone, the doctor can see inside your body without cutting you open. NDT technicians do the same thing for aircraft, spacecraft, and defense systems—except instead of bones, they’re examining turbine blades, wing spars, fuselage sections, and rocket components worth millions of dollars.

The Four Core Methods Every NDT Trainee Learns

1. Magnetic Particle Testing (MT)

Imagine sprinkling iron filings on a magnetized surface—they naturally cluster around any cracks or discontinuities. MT technicians use this principle to find surface and near-surface defects in ferromagnetic materials. It’s simple, fast, and devastatingly effective for detecting the hairline cracks that could ground a $150 million aircraft.

2. Liquid Penetrant Testing (PT)

This is the “CSI: Aviation” method. Technicians apply a brightly colored or fluorescent liquid to a component’s surface. The liquid seeps into any cracks (even ones microscopic in size), then they apply a developer that pulls the penetrant back out, making defects glow under UV light. It works on virtually any non-porous material and requires zero electricity.

3. Ultrasonic Testing (UT)

Remember Marcus and his sound-wave screen? This is UT—using high-frequency sound waves to detect internal flaws. The technician places a transducer (think ultrasound wand) on the material, and sound waves travel through it. When they hit a defect, they bounce back differently. Advanced UT can measure material thickness to within thousandths of an inch and find defects deep inside solid metal.

4. Eddy Current Testing (ET)

This is electromagnetic wizardry. When you pass an alternating current through a coil near conductive material, it creates “eddy currents” in that material. Any defect disrupts these currents in predictable ways. ET is perfect for finding cracks in aircraft skin, detecting corrosion under paint, and measuring coating thickness—all without touching the surface.

Each method has its superpower, and NDT technicians become fluent in all four during their training.

The Salary Ladder: From Trainee to Six-Figure Expert

Here’s what the money actually looks like, based on 2026 industry data from the Bureau of Labor Statistics and salary surveys from the American Society for Nondestructive Testing:

| Level | Experience | Salary Range | Typical Responsibilities |

|---|---|---|---|

| Trainee/Helper | 0-6 months | $40,000-$55,000 | Learning procedures, assisting certified techs, basic prep work |

| Level I | 6-18 months | $50,000-$70,000 | Performing basic testing under supervision, documenting results |

| Level II | 2-5 years | $70,000-$95,000 | Independent testing, interpreting results, training Level I techs |

| Level III | 5+ years | $95,000-$150,000+ | Writing procedures, managing quality programs, final authority on test interpretation |

The premium positions: NDT technicians working for defense contractors, aerospace manufacturers, or specialized inspection firms like Applus+ or Mistras Group can command even higher salaries. Level III technicians at companies like Precision Castparts (a Berkshire Hathaway subsidiary supplying Boeing and Airbus) routinely clear $130,000-$160,000, especially when factoring in overtime and per diem for travel assignments.

Travel technicians—those willing to deploy to aircraft maintenance facilities, shipyards, or manufacturing plants nationwide—can add another $20,000-$40,000 annually through per diem payments that cover housing, meals, and transportation.

The “No-Experience” Paradox: How to Actually Get Hired

Here’s the beautiful contradiction at the heart of NDT: you don’t need experience to get hired, but you do need to prove you’re trainable and reliable.

The Minimum Requirements (Seriously, That’s It)

- High school diploma or GED

- Clean background check (aviation security clearances matter)

- Decent vision (correctable to 20/30 for close-up work)

- Basic math skills (think high school algebra, not calculus)

- No criminal record involving theft or deception (you’ll be working around million-dollar equipment)

Notice what’s NOT on that list? A college degree. Years of experience. Technical certifications coming in the door.

The Real Hiring Path

Step 1: Target companies that train in-house

Major players like Boeing, Lockheed Martin, Northrop Grumman, and inspection service providers like Mistras Group and Acuren actively recruit NDT trainees. They prefer blank slates they can train to their exact specifications.

Step 2: Ace the interview by showing three things

- Reliability: Emphasize attendance records, commitment, follow-through from previous jobs

- Attention to detail: Share examples of when you caught mistakes or noticed small discrepancies

- Willingness to learn: Express genuine interest in the technology and advancement path

Step 3: Understand the certification timeline

Companies will train you toward NAS 410 or SNT-TC-1A certification (industry standards for aerospace NDT). You’ll need:

- 40 hours of classroom training per method

- Supervised practical experience (varies by method and level)

- Written, practical, and vision exams

Most trainees achieve Level I certification in their first method within 3-6 months. Level II typically requires 1-2 years of experience and additional training.

The Secret Weapon: Community College Programs

While not required, completing an NDT certificate program at a community college can fast-track your hiring. Schools like Tulsa Welding School, Los Angeles Trade-Technical College, and Edmonds College (near Seattle) offer 3-12 month programs costing $3,000-$12,000—a fraction of a bachelor’s degree and directly applicable to employment.

Many companies will even reimburse tuition if you commit to working for them post-graduation.

Geographic Gold Mines: Where the Jobs Actually Are

NDT aviation jobs aren’t evenly distributed—they cluster around aerospace manufacturing hubs and major aircraft maintenance facilities.

Seattle/Everett, Washington: The Boeing Belt

With Boeing’s massive production facilities in Everett and Renton, plus hundreds of aerospace suppliers, the Puget Sound region is NDT central. Companies like Boeing, Spirit AeroSystems, and inspection contractors are perpetually hiring. Entry-level positions regularly start at $52,000-$60,000, with overtime pushing first-year earnings above $65,000.

The catch? Cost of living is brutal. A studio apartment in Everett runs $1,600+/month. But for NDT techs, the trade-off is access to the industry’s most advanced training and fastest advancement paths.

Los Angeles/Long Beach, California: Aerospace Diversity

Southern California hosts SpaceX, Northrop Grumman, Boeing (El Segundo), and dozens of defense contractors. The region offers incredible variety—you might inspect rocket components one month and stealth aircraft the next.

Starting salaries run $48,000-$58,000, but California’s premium pay scales and abundant overtime mean second-year techs often crack $75,000. The aerospace supply chain here is so dense that job mobility is exceptional—Level II techs can easily jump between companies for $10,000-$15,000 raises.

Wichita, Kansas: The Air Capital

Lower cost of living meets serious aerospace concentration. Spirit AeroSystems (Boeing’s largest supplier), Textron Aviation, and Bombardier all maintain major facilities here. Entry-level positions start at $42,000-$50,000, but housing costs are 60% lower than Seattle or LA.

For NDT techs willing to embrace the Midwest, Wichita offers the fastest path to homeownership and financial stability.

Phoenix/Tucson, Arizona: Defense and MRO Hub

Raytheon, Northrop Grumman, and multiple aircraft maintenance, repair, and overhaul (MRO) facilities create steady NDT demand. The dry climate is perfect for aircraft storage and maintenance, making Arizona a growing hub. Starting salaries of $45,000-$55,000 stretch further with Arizona’s moderate cost of living.

Provo/Salt Lake City, Utah: The Silicon Slopes Aerospace Boom

Utah’s “Silicon Slopes” aren’t just tech startups—they’re also home to Northrop Grumman, L3Harris, and a growing aerospace manufacturing base. Entry-level NDT positions start at $46,000-$54,000, with Utah’s business-friendly environment attracting new aerospace contracts constantly.

Inside the Inspection Giants: Who Actually Hires?

Mistras Group

One of the world’s largest inspection service providers, Mistras deploys NDT technicians across aerospace, energy, and infrastructure sectors. They’re known for hiring trainees aggressively and offering tuition reimbursement for ASNT certification. Travel techs can live anywhere and deploy nationwide—expect 200+ days on the road but earnings of $80,000-$100,000 by year three.

Applus+

This Spanish-owned inspection giant operates globally but maintains massive U.S. operations. Their aerospace division works with every major OEM and airline. Applus+ is famous for fast-tracking promising trainees—multiple current Level III technicians started as complete beginners and reached top-level certification within seven years.

Acuren (formerly Mistras sister company)

Post-merger rebranding created Acuren, focusing heavily on advanced NDT techniques. They invest heavily in training, particularly for emerging methods like phased array ultrasonics and computed radiography. Trainees here get exposure to cutting-edge technology that makes them highly marketable.

Direct Manufacturer Employment: Boeing, Lockheed, Northrop Grumman

Working directly for aerospace manufacturers typically means slightly lower starting pay ($48,000-$56,000) but incredible benefits, job security, and advancement into quality engineering or management roles. Boeing NDT technicians often transition into aerospace quality engineering positions paying $95,000-$120,000 after 5-7 years.

The Skills That Set You Apart

Every NDT trainee learns the core methods, but the ones who advance fastest develop these additional competencies:

Digital radiography proficiency: Traditional film X-ray is dying. Computed radiography and digital detector arrays are the future—get trained early.

Data analysis skills: Modern NDT generates massive datasets. Techs who can use software like MATLAB or Python to analyze ultrasonic data become invaluable.

Composite materials expertise: As aerospace moves toward carbon fiber composites, NDT techniques must evolve. Thermography and ultrasonic testing of composites is a specialized, high-paying niche.

Robotics and automation: Crawlers and drones increasingly carry NDT sensors into confined or dangerous spaces. Techs who can program and operate these systems command premium pay.

Written communication: NDT reports become legal documents in failure investigations. Technicians who write clear, defensible reports advance fastest into leadership positions.

[Link: Your Website – “How to Build a Technical Resume”]

The Dark Side: What They Don’t Tell You in the Recruiting Pitch

Let’s be honest—NDT isn’t perfect. Here’s what makes techs quit:

The schedule flexibility myth: “Flexible schedule” often means “we’ll call you at 5 p.m. Friday and ask you to fly to Oklahoma for a Monday morning inspection.” New techs have minimal control over scheduling.

Physical demands: You’ll crawl into confined spaces, work at heights, and spend hours in uncomfortable positions. That aircraft wing inspection? It happens in a 3-foot-tall crawlspace in 90-degree heat.

Certification pressure: Fail your Level II exam three times and you’re basically done in aerospace NDT. The tests are genuinely difficult—expect 30-40% failure rates on first attempts.

Radiation exposure: Radiographic testing uses real X-rays. While strictly controlled and monitored, some people are uncomfortable with any occupational radiation exposure.

Repetitive stress: Performing the same inspection motions hundreds of times daily leads to shoulder, wrist, and back issues for some techs. Ergonomics matter.

Future-Proofing: Is This Job Safe from AI and Automation?

The short answer: NDT is one of the most automation-resistant careers in existence.

Here’s why: NDT requires physical presence, tactile judgment, and real-world problem-solving in unpredictable environments. You can’t remote into a titanium bulkhead inspection. AI can help interpret ultrasonic data, but it can’t climb into a fuel tank to position the transducer correctly.

The Bureau of Labor Statistics projects 7% growth for NDT technicians through 2032—faster than average—driven by aging aircraft fleets, increased safety regulations, and aerospace manufacturing expansion.

Moreover, as AI and automation advance, they become tools that enhance NDT techs’ capabilities rather than replace them. Phased array ultrasonics, automated scanning systems, and AI-assisted defect recognition all require skilled operators and interpreters.

The FAA and aviation manufacturers are extraordinarily conservative about automation in safety-critical roles. Your job security is backed by thousands of pages of regulations requiring human judgment.

[Link: Your Website – “Top 10 Trade Careers of 2026”]

The Verdict: Who Should Actually Pursue This Path?

You’re a great fit if:

- You’re detail-oriented and patient (finding defects requires methodical precision)

- You enjoy technology and learning new equipment

- You want geographical flexibility (NDT skills transfer across industries and locations)

- You prefer tangible, meaningful work over abstract tasks

- You’re willing to travel or relocate for the right opportunity

- You value continuous learning and certification advancement

Think twice if:

- You need complete schedule predictability

- You have physical limitations around confined spaces or awkward positions

- You struggle with written exams and testing pressure

- You’re pursuing this purely for money without interest in the work itself

- You expect rapid advancement without putting in study time

Taking the First Step Tomorrow

If you’ve read this far and you’re intrigued, here’s your action plan:

- Research employers in your target region: Start with company careers pages for Boeing, Lockheed, Northrop Grumman, Mistras, and Applus+

- Connect with ASNT: Visit asnt.org and explore their certification guides, find local chapters, and attend free webinars

- Consider a certificate program: If you’re risk-averse, a 6-month community college NDT program provides credentialing before job hunting

- Network on LinkedIn: Search “NDT Technician” and connect with professionals at your target companies—most are surprisingly responsive to genuine inquiries

- Apply broadly: Don’t wait until you feel “ready.” Companies expect to train you. Your job is to show up reliable, drug-free, and eager to learn

Marcus Chen, the former Best Buy employee we met at the beginning? He recently passed his Level II certification in ultrasonic testing. At 25, he’s now earning $74,000, owns a condo in Long Beach, and has zero student loan debt.

“My roommate from community college just graduated with his bachelor’s in marketing,” Marcus says. “He’s making $45,000 doing social media for a plumbing company and complaining about AI taking jobs. Meanwhile, I’m literally the guy who decides if a SpaceX rocket is safe to fly. No robot’s doing that.”

He’s right. And there are thousands of positions like his waiting to be filled across America—high-tech, well-paid, and automation-proof. The only question is whether you’re ready to stop thinking of “trades” as a backup plan and start seeing them as the strategic career move they’ve become.

The aircraft needs inspecting. The job pays six figures. And no, you don’t need a college degree.

FAQ: Your Top 5 Questions About Entry-Level NDT Aviation Jobs

1. Do I need a college degree to become an NDT technician?

No. The minimum requirement is a high school diploma or GED. Most aerospace employers prefer to hire trainees without prior experience and train them to company-specific standards. While a community college NDT certificate can accelerate your hiring and advancement, it’s not mandatory. Focus on reliability, attention to detail, and willingness to learn during interviews.

2. How long does it take to get certified and start making serious money?

You can achieve Level I certification in your first NDT method within 3-6 months of starting employment. Most techs reach Level II (where salaries jump to $70,000-$95,000) within 2-3 years. Level III certification, which unlocks $95,000-$150,000+ positions, typically requires 5-7 years of experience plus additional training. The timeline depends on your work ethic, study habits, and employer training resources.

3. Is NDT a “future-proof” job with AI and automation advancing?

Yes. NDT is one of the most automation-resistant careers because it requires physical presence, tactile judgment, and problem-solving in unpredictable environments. You can’t remote into an aircraft wing inspection or ask AI to crawl into a fuel tank. Automation enhances NDT work through better data analysis and scanning tools, but skilled human operators remain irreplaceable. Federal regulations and safety requirements ensure human judgment stays central to aerospace inspection.

4. Can I travel for this job, and is it worth it financially?

Absolutely. Travel NDT technicians—those willing to deploy to facilities nationwide—can add $20,000-$40,000 annually through per diem payments covering housing, meals, and transportation. Companies like Mistras Group and Applus+ specifically hire travel techs who live anywhere but work on-site at customer facilities for weeks or months at a time. Expect 200+ days on the road annually, but second-year travel techs often earn $75,000-$85,000 total compensation. It’s ideal for young professionals without family obligations.

5. What is the hardest part of being an NDT trainee?

Certification exam pressure. The written and practical exams for Level I and II certification have 30-40% first-attempt failure rates. The exams test both theoretical knowledge and hands-on skills under strict time limits, and failing three times essentially ends your aerospace NDT career. Additionally, the physical demands—crawling into confined spaces, working at heights, maintaining awkward positions for hours—surprise many new techs. The work requires both mental focus and physical endurance that desk jobs don’t prepare you for.