TL;DR

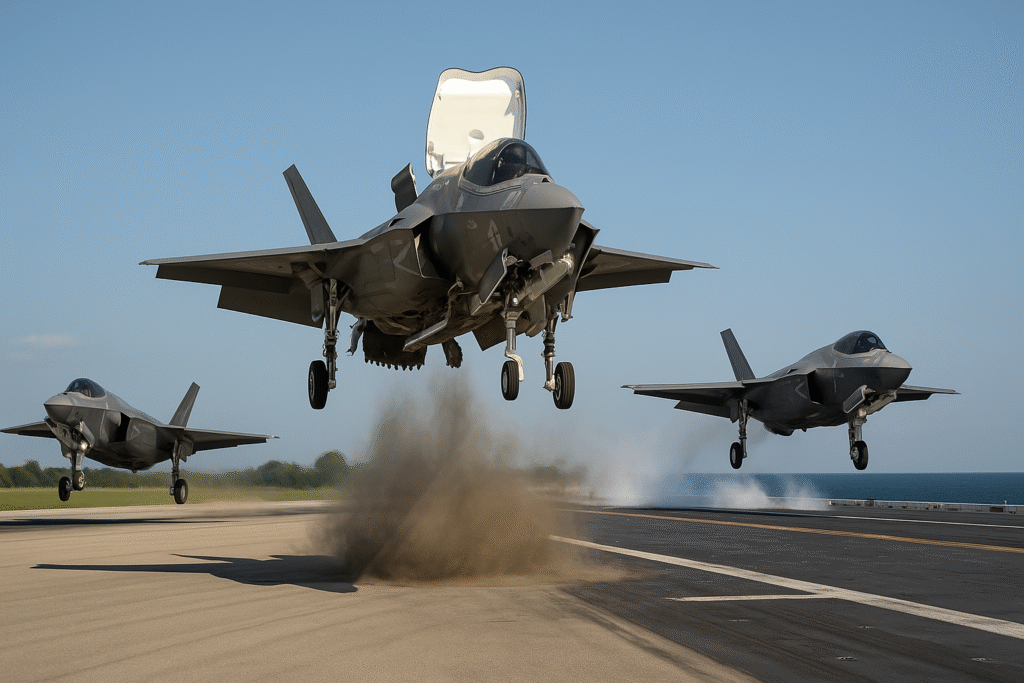

The F-35 engine—Pratt & Whitney’s F135—delivers more than 40,000 lb of thrust, integrates low-observable (stealth) treatments, and (on the F-35B) works with Rolls-Royce’s LiftSystem for short takeoff/vertical landing. To support hotter, more power-hungry Block 4 sensors and weapons, the program is fielding the Engine Core Upgrade (ECU) while evaluating a new cooling system. The U.S. opted not to integrate adaptive engines in the near term, prioritizing an F135 upgrade path to keep costs and logistics under control. The Aviationist+5Pratt & Whitney+5Rolls-Royce+5

What powers the F-35?

At the heart of every F-35 is the Pratt & Whitney F135, a single-spool, afterburning turbofan derived from the F119 (F-22) lineage, tuned for high thrust, reliability, and low observability. Public figures cite 40,000+ pounds of thrust with advanced digital engine controls and thermal management sized for a 5th-gen mission system stack. In short: one engine that must do it all—power, cooling, and stealth—across three variants (A, B, C). Pratt & Whitney

A single engine, three missions

- F-35A (USAF) and F-35C (USN) use the F135 in conventional roles (runway takeoff/landing for A; carrier ops for C).

- F-35B (USMC/partners) adds short takeoff/vertical landing (STOVL) capability using Rolls-Royce’s LiftSystem paired to the F135: a 50-inch, two-stage, counter-rotating LiftFan up front, a three-bearing swivel nozzle (3BSM) at the rear, and roll-post nozzles in the wings for lateral control. The LiftFan contributes ~20,000 lbf of cool thrust—critical for vertical lift while keeping deck temperatures manageable. Rolls-Royce+1

Why this matters: The LiftSystem lets an F-35B bring meaningful fuel and weapons off short decks or austere sites—something no other stealth fighter can match—without compromising the baseline F135’s core performance in forward flight. The official program site also lists variant-specific thrust and vertical lift figures, underscoring how the propulsion system is tailored to each jet’s mission. f35.com

Stealth isn’t just skin-deep

When people think “stealth,” they picture saw-toothed panel lines and radar-absorbent materials. But the engine contributes to low observability too:

- Infrared signature management: The F135’s integration with the airframe and nozzle geometry helps reduce hot-spot visibility from certain aspects.

- Smooth external flow: Compatible inlets and boundary-layer management keep radar returns down while feeding the fan efficiently at high AOA.

- Digital control integration: Engine control logic coordinates with aircraft systems to balance power demands (electrical and pneumatic) without compromising signature where possible.

These are integration choices as much as engine design—stealth is a system-of-systems, not a single ingredient. (Program literature and OEM materials consistently emphasize the F135’s “low observable signature” alongside thrust and reliability.) Pratt & Whitney

The big 2020s challenge: heat, power, and Block 4

The Block 4 upgrade wave adds new sensors, EW features, and weapons—great for combat, tough on power and cooling. The Government Accountability Office (GAO) has repeatedly flagged Power & Thermal Management System (PTMS) shortfalls and schedule risk, noting that meaningful cooling upgrades aren’t expected before ~2030–2032, and Block 4 content has slipped. Translation: the jet’s future brains need more “oomph” from propulsion to stay cool and fully functional on long, hot missions. U.S. Government Accountability Office+1

Where things stand: Lockheed and the Joint Program Office have signaled a new cooling unit—often referred to as a PTMU/PTMS modernization—will have to work with an upgraded F135 to meet Block 4 and beyond. A down-select for that new cooling architecture has been discussed on roughly a two-year timeline. Breaking Defense

The chosen path: Engine Core Upgrade (ECU)

Rather than swapping to a brand-new adaptive engine, the program selected the F135 Engine Core Upgrade (ECU)—a mid-life modernization focused on hot-section durability, efficiency, and added power/thermal headroom. Advantages:

- Retrofit-friendly across A/B/C variants (minimizes fleet fragmentation).

- Lower integration risk vs. a wholesale engine change.

- Supports Block 4 by unlocking more thermal margin in the near term.

As of mid-2024, Pratt & Whitney completed Preliminary Design Review for ECU with U.S. funding in place—an important gate on the way to detailed design, test, and fielding. Reuters+1

Why not adaptive engines (for now)?

You may have heard of AETP (Adaptive Engine Transition Program) demonstrators—GE’s XA100 and Pratt’s XA101—promising big gains in fuel efficiency, range, and thermal capacity via a third “adaptive” stream of air. The Department of Defense decided not to integrate an adaptive engine into the F-35 in the near term, due to cost/schedule/logistics trade-offs and the complexity of fielding different propulsion baselines across a global fleet. Adaptive work continues for next-gen air dominance platforms, but ECU is the F-35’s near-term answer. The Aviationist+1

Performance, reliability, and sustainment

A frontline fighter engine must deliver thrust on demand and be maintainable at scale. Public materials emphasize that the F135 has demonstrated a step-change in readiness and reliability over legacy 4th-gen engines, supported by:

- Modular hot-section design to streamline depot work.

- Advanced engine health monitoring and digital controls to predict issues early.

- Global sustainment—shared spares, repair lines, and data across partner fleets.

These elements don’t show up on a spec sheet, but they’re crucial to real-world sortie generation and cost per flight hour. Pratt & Whitney

Powering tomorrow’s payloads: what comes next

Even with ECU, the F-35’s “thermal budget” will be tight as post-Block 4 sensors and electronic warfare options mature. GAO’s 2025 snapshot underscores how propulsion and thermal modernization—along with lifecycle costs across ~2,470 jets—drive the program’s long-term bill. Expect:

- ECU fielding to roll into the fleet as aircraft cycle through depot.

- A new cooling architecture decision and integration (to complement ECU).

- Continued adaptive-engine R&D for future platforms (e.g., Navy F/A-XX, Air Force NGAD), which could inform a later-life F-35 path if cost/risk equations change. U.S. Government Accountability Office+2Breaking Defense+2

Key specs & fast facts (at a glance)

- Engine: Pratt & Whitney F135 (variants: PW-100 / -400 / -600)

- Thrust class: 40,000+ lbf (afterburning)

- STOVL (F-35B): Adds Rolls-Royce LiftSystem—50-inch LiftFan (~20,000 lbf), 3BSM swiveling nozzle, roll posts for lateral control

- Upgrade path: ECU for durability/thermal headroom; new PTMS/PTMU concept under evaluation

- Adaptive engines: Not integrated on F-35 in near term; R&D continues for future fighters

The Aviationist+3Pratt & Whitney+3Rolls-Royce+3

Frequently Asked Questions (FAQ)

1) How much thrust does the F-35 engine make?

Public sources cite more than 40,000 pounds of thrust for the F135—placing it among the most powerful fighter engines flying today. Pratt & Whitney

2) What makes the F-35B lift off vertically?

The F135 couples to a Rolls-Royce LiftSystem: a 50-inch, two-stage LiftFan (~20,000 lbf) up front, a 3-bearing swivel nozzle in back, and roll-post nozzles in the wings. The combo balances cool fan thrust with vectored hot exhaust for stable vertical lift. Rolls-Royce

3) Why is everyone talking about “thermal management”?

New sensors and EW packages are power-hungry and heat-intensive. Without more cooling, avionics may need to throttle performance. That’s why the program is pursuing ECU plus a modernized cooling unit; GAO estimates substantial upgrades arriving around 2030–2032. U.S. Government Accountability Office

4) What exactly is the Engine Core Upgrade (ECU)?

ECU refreshes the F135’s core—hot-section durability, materials, and efficiency—freeing power/thermal headroom for Block 4 while preserving fleet commonality. It passed Preliminary Design Review in 2024. Reuters

5) Did the F-35 get an adaptive engine?

No—not in the near term. The Pentagon didn’t select an adaptive engine for F-35 fielding, preferring the ECU path; adaptive R&D continues for future jet programs. The Aviationist