What are morphing wings and why biomimicry matters

Morphing wings are aircraft wings that change shape in flight to match the mission phase, inspired by birds that alter camber, twist, and span for takeoff, climb, cruise, and landing. Instead of relying only on hinged flaps and slats, morphing concepts use flexible structures and smart actuators to optimize lift-to-drag in real time. NASA’s aeronautics program outlines the idea of adaptive structures and aeroelastic control across multiple projects, from variable-camber airfoils to load-alleviating wing twist (NASA Aeronautics). The U.S. Air Force Research Laboratory has studied active aeroelastic wings and advanced structures to reduce drag and weight (Air Force Research Laboratory). European research programs, including Airbus efforts like the AlbatrossOne demonstrator, explore bird-inspired tips and flexible control surfaces to cut fuel burn and noise (Airbus Innovation).

The efficiency levers

Adaptive camber and twist reduce profile and induced drag at cruise while adding lift at low speed, which can shorten takeoff and landing distances and improve climb rates. Seamless, gapless surfaces eliminate leakage and vortex generators that come from traditional hinges, improving laminar flow. Load-alleviation morphing can mitigate gusts and redistribute lift, trimming structural margins or enabling lighter wings. These benefits compound on long sectors where even small drag reductions translate into significant fuel and CO₂ savings. For urban air mobility and eVTOL platforms, morphing can help with low-noise, efficient transitions from vertical to wing-borne flight, where every watt matters (EASA AAM overview and FAA advanced air mobility).

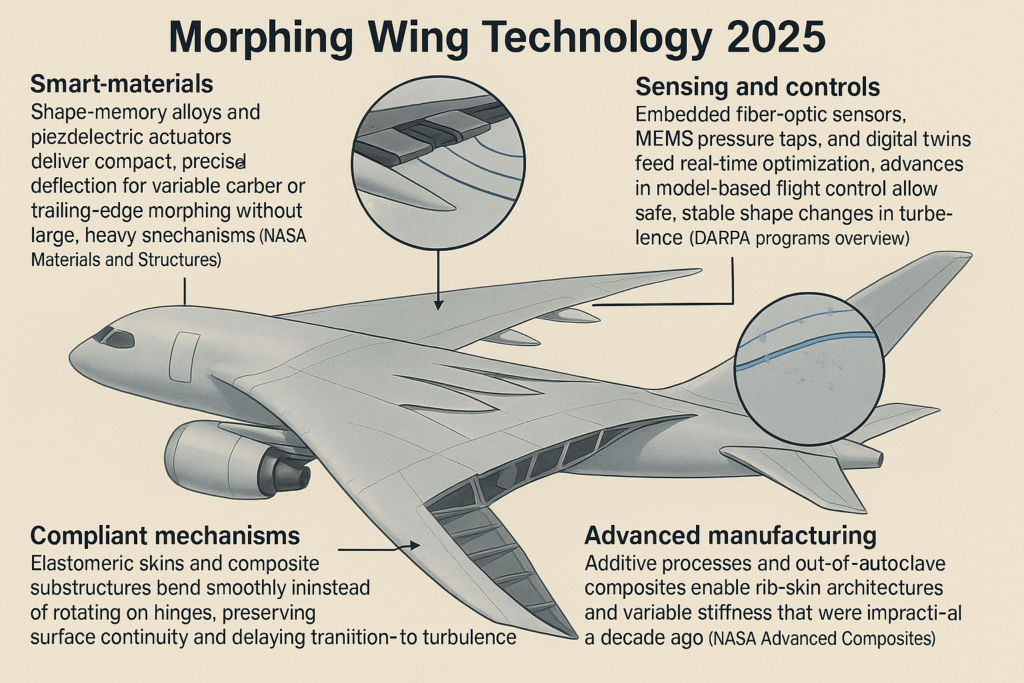

Enabling technologies in 2025

Smart materials. Shape-memory alloys and piezoelectric actuators deliver compact, precise deflection for variable camber or trailing-edge morphing without large, heavy mechanisms (NASA Materials and Structures).

Compliant mechanisms. Elastomeric skins and composite substructures bend smoothly instead of rotating on hinges, preserving surface continuity and delaying transition to turbulence.

Sensing and controls. Embedded fiber-optic sensors, MEMS pressure taps, and digital twins feed real-time optimization; advances in model-based flight control allow safe, stable shape changes in turbulence (DARPA programs overview).

Advanced manufacturing. Additive processes and out-of-autoclave composites enable rib-skin architectures and variable stiffness that were impractical a decade ago (NASA Advanced Composites).

Where morphing helps most in the near term

Regional and business aviation. Smaller wings and lower certification complexity make variable-camber trailing edges attractive for short runways and mixed mission profiles.

UAVs and HALE platforms. Long-endurance drones benefit from continuous camber control to maintain efficiency across large altitude and temperature swings; soft gust-load alleviation extends airframe life.

eVTOL and tilt-wing concepts. Smooth, noise-sensitive operations gain from seamless surfaces and adaptive tips that reduce vortex noise in approach and departure (EASA eVTOL topic hub).

Case studies and programs to watch

NASA has published multiple demonstrations on variable-camber and flexible trailing-edge concepts, showing how seamless skins can maintain lift with less drag and noise than conventional flaps (NASA Aeronautics—Research Highlights).

The U.S. Air Force’s work on Active Aeroelastic Wing proved the value of using structural flexibility for control, lowering trim drag and expanding maneuver efficiency (Air Force Research Laboratory).

Airbus’s Albatross-inspired wingtip experiments explore semi-aeroelastic tips that adapt to gusts and reduce loads, pointing to future commercial wing architectures (Airbus Innovation).

Certification frameworks for adaptive structures are progressing under existing rules using performance-based and safety-objective approaches with special conditions where needed; see the FAA’s design approvals portal and EASA guidance for novel structures (FAA Design Approvals, EASA Certification).

Engineering challenges you must solve

Structural safety and fail-safe behavior. Regulators expect a clear load path if a morphing element jams or loses power; the aircraft must remain controllable. Flutter margins. Adaptive wings shift aeroelastic modes; robust analysis, ground vibration testing, and envelope protection are essential. Environmental durability. Flexible skins must resist temperature cycles, de-icing fluids, UV, and sand while staying smooth and airtight. Maintenance and MRO. Inspectability is critical. Operators will need non-destructive evaluation procedures and clear intervals for skins, actuators, and sensors (FAA Continued Airworthiness, EASA Continuing Airworthiness). Cost and weight. Benefits must outweigh added mass and complexity; business cases improve when morphing replaces multiple discrete mechanisms and lowers parasite drag.

Business case and ROI snapshot

Fuel and emissions. Even modest drag reductions over long fleets and years translate into large fuel savings and lower Scope 1 emissions, supporting corporate targets and access to green finance instruments. Cabin comfort and community noise. Gapless morphing control surfaces can reduce tonal noise from flap edges during approach, complementing other low-noise treatments. Payload and range. Gust-load alleviation permits either lighter structures for the same mission or the same structure with more payload or reserve fuel, especially relevant in hot-and-high operations. Retrofit vs. line-fit. New-build aircraft can embed morphing in the primary structure; retrofits will focus on modular trailing edges, adaptive tips, or control-law-based aeroelastic gains without major structural changes. For policy context on emissions accounting and incentives, see ICAO and CORSIA resources and U.S. SAF credit programs (ICAO CORSIA, U.S. DOE SAF overview).

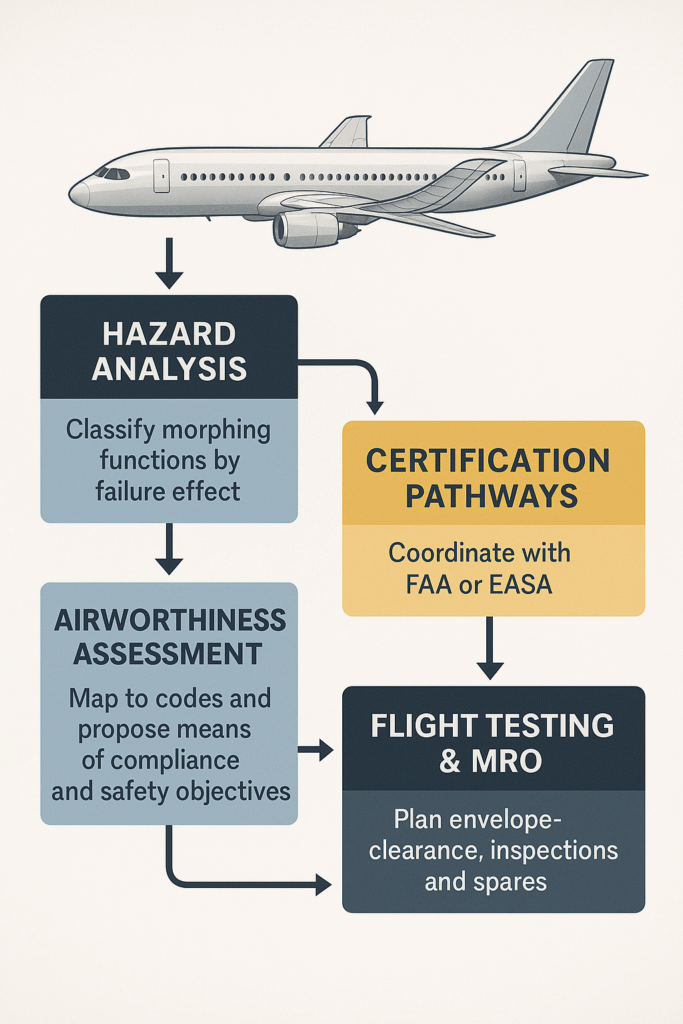

Certification and compliance roadmap

Start with an aircraft-level hazard analysis to classify morphing functions by failure effect. Map each function to applicable paragraphs in the airworthiness codes, then propose means of compliance and safety objectives. For U.S. projects, coordinate early with the FAA on special conditions or issue papers via the Organization Designation Authorization pathway; for European projects, align with EASA’s performance-based approach and Acceptable Means of Compliance for structures and flight controls (FAA Certification Pathways, EASA AMC/GM). Plan flight-test campaigns that sweep aeroelastic boundaries deliberately, with tailored instrumentation and envelope-clearance steps. Build MRO documentation in parallel so operators understand inspection intervals, limits, and spares provisioning.

2025–2030 outlook

Expect UAVs, business jets, and regional types to adopt the first commercial morphing products: adaptive trailing edges, compliant flaperons, and semi-aeroelastic tips. Single-aisle airliners will likely trial morphing subassemblies on testbeds before committing to line-fit. eVTOL manufacturers are closest to serial adoption, where low-noise, low-drag surfaces can meaningfully impact battery sizing and reserve rules. As CAT-IIs of morphing components mature, regulators will have more service data to incorporate into mainstream rules, reducing reliance on one-off special conditions. Keep an eye on NASA flight demos, AFRL projects, and Airbus research pages for the latest milestones (NASA Aeronautics, AFRL, Airbus Innovation).

FAQs for readers and investors

What is the difference between morphing and conventional high-lift systems

Morphing maintains a smooth surface and changes shape continuously; flaps and slats hinge, creating gaps and added drag and noise.

Is morphing only for new aircraft

No. Some concepts are modular and can be trialed as retrofit control surfaces or tips, subject to certification and structural margins.

How does morphing interact with fly-by-wire

Flight control laws can command shape changes as part of stability, gust-load alleviation, and performance optimization, with redundancy to meet safety objectives.

Related reading on AviationTitans

Explore more future airframe ideas in Experimental & Future Aircraft. For propulsion advances that pair well with aerodynamic gains, see Industry News & Market Trends and our eVTOL insights. For passenger-facing benefits, check In-Flight Experience Reviews.

Want me to add three royalty-free image prompts with alt text and captions tailored to this post, or generate per-section callouts you can reuse as social cards?