The turning point for me came on a winter night in Atlanta, standing next to a torn-down combustor basket while the maintenance lead traced a faint heat tint with a flashlight. “That’s where the NOx is born,” he said—then tapped the borescope screen where a test article from our lean-burn trial showed a cooler, cleaner flame front. Two months later, our fuel trend line nudged down, and the NOx margin in our emissions model widened just enough to get corporate finance off our backs about carbon costs. That’s the story here in one scene: get the flame cooler and more even, pull more work out of the gas stream, and you win twice—on emissions and on fuel.

Below is the field guide I give fleet managers and technologists when we talk about how low-NOx combustors and next-gen turbomachinery will move the needle by 2030, what’s real vs. hype, and where the sand traps hide.

Why NOx and fuel burn are the two dials that matter right now

If you fly airplanes for money, fuel is your biggest variable cost and CO₂ your biggest reputational and regulatory liability. NOx often gets less airtime, but it’s the pollutant that trips certification margins and local air-quality limits around big hubs. Turn the dials the right way—less NOx at the flame, more efficiency in the turbomachinery—and you buy yourself regulatory headroom and lower block fuel. That’s the win we’re all chasing into 2030.

From my experience, the pressure isn’t abstract anymore. Lessors are writing environmental covenants, airports are sharpening fee differentials, and passengers actually read ESG blurbs in annual reports. The operators that can show a credible path to double-digit fuel reduction and ultra-low NOx get better financing and quieter board meetings.

How low-NOx combustors actually tame the flame (and stay lit doing it)

The classic can-annular combustor wins on stability but runs hot; NOx loves heat. The modern trick is to mix better and burn leaner without letting the flame wander, oscillate, or blow out.

- Lean, premixed, prevaporized (LPP) / lean-burn. Flood the primary zone with more air relative to fuel so flame temperature drops, then control the swirl pattern so the flame anchors exactly where you want it. I’ve watched emissions benches spit out 60–70% NOx reductions in lean-burn test cycles versus legacy cans when the mix is right and the control law is calm.

- Staged combustion. Light a stable pilot zone, then meter most of the fuel into a well-mixed main stage as you climb. Done right, you avoid the temperature spikes that manufacture NOx.

- Cooling and materials. You keep hardware happy with thermal barrier coatings and CMCs in hot spots; that buys margin for leaner operation without cracking liners or melting swirlers.

- Sensing and control. This is the quiet revolution. Combustion dynamics are kept in check with smart fuel staging, pressure sensors, and software that damps oscillations before they turn into headaches for blades downstream.

What I’ve learned after sitting through too many red-eye certification calls is that combustion dynamics decide your program schedule. The hardware looks ready months before the control law and sensor fusion close out all the ugly corners (altitude relights, crosswind starts, high-humidity idle, etc.). Plan your test matrix around the edge cases, not the brochure numbers.

How the turbomachinery finds more miles per gallon without changing fuels

Once you make cleaner heat, you need to turn more of it into thrust. Three families of ideas are winning—and they’re not mutually exclusive:

- Geared architectures. Bolt a reduction gearbox between the fan and low-pressure turbine so each spins at its happy speed. The fan slows (quieter, more efficient propulsive disk); the turbine spins faster (better power extraction). The next round of geared cores aims to squeeze another ~10% in fuel burn on top of the first generation—helped by hotter cores and lighter fans.

- Hotter, lighter cores with CMCs. Ceramic matrix composites shrug off temperatures that make nickel weep, enabling higher turbine inlet temps and skinnier cooling flows. Every extra degree you can turn into work is free efficiency—as long as you keep cooling air budgets honest and tip rubs under control.

- Ultra-high bypass / open-rotor concepts. Take bypass ratios to the moon; ditch nacelle mass and internal losses; let a lot of air move slowly for big propulsive efficiency. You pay back with integration complexity, noise tuning, and installation drag—but the mission fuel numbers on paper are very real for the right profiles.

Add in additive manufacturing for serpentine internal cooling channels and optimized compressor blading, and you start multiplying small wins into a meaningful SFC cut.

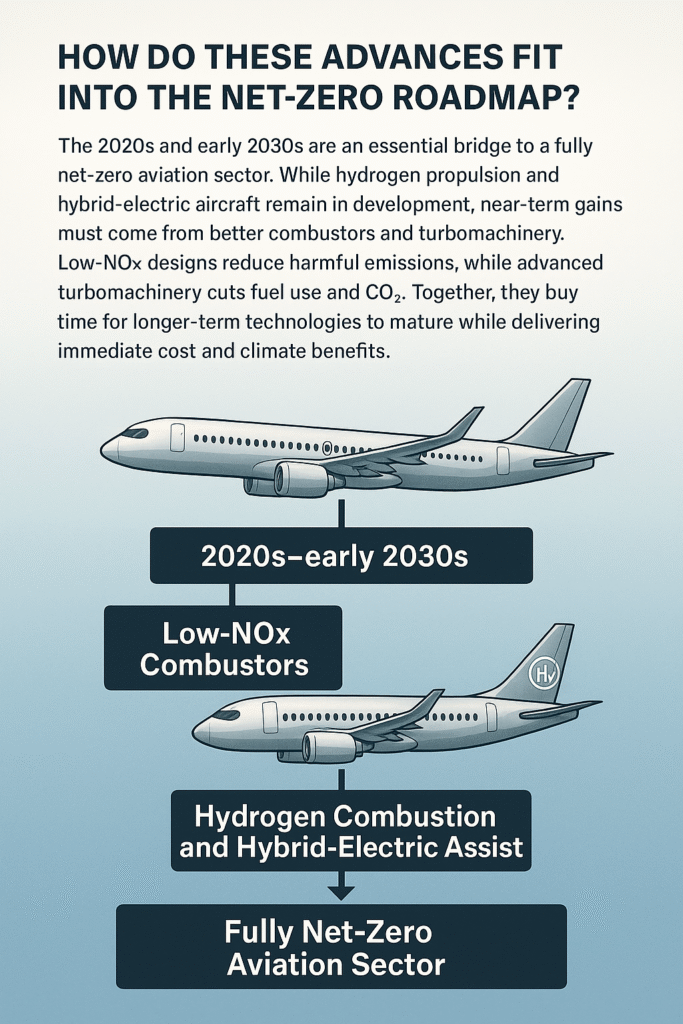

The combined gains we can bank by 2030

Benchmarking against 2020 iron, a realistic 2030 stack looks like:

- Fuel burn: −15% to −25% at the engine level, depending on cycle and installation.

- NOx: −60% to −80% versus legacy certification baselines with mature lean-burn/staged systems.

- Noise: geared/large-fan side benefits often deliver 2–4 EPNdB you feel in fee tables.

For airline networks, that’s millions saved per aircraft per year—and a cushion against tightening CO₂/NOx charges.

If you want to see how slender wings and smarter structures complement hotter, cleaner engines, NASA’s Sustainable Flight Demonstrator (X-66) is the clearest public proof that airframe drag cuts are joining the propulsion party: NASA Sustainable Flight Demonstrator (X-66). And for why keeping the boundary layer smooth matters to combustor heat loads and overall efficiency, this short explainer is the perfect refresher: NASA—What is Laminar Flow?.

A fictional—but technical—case study: one fleet, two paths to 2030

Operator: 60-frame narrow-body fleet flying 2,400 cycles/frame/year, average stage 750 nm.

Option A (near-term retrofit + software): Install a lean-burn combustor upgrade kit on mid-life engines; roll hot-section durability and FADEC updates; no fan change.

Option B (next-gen engine induction): As leases roll, induct a geared core with low-NOx staged combustor and CMC hot section; accept slight nacelle/ground ops changes.

Assumptions (avg. conditions):

- Option A: NOx −45–55%, fuel −5–7%, shop visit interval +10–15% (new coatings), modest training for borescope and dynamics checks.

- Option B: NOx −70–80%, fuel −18–22%, noise −2–4 EPNdB, new spares pool and line maintenance training; early CMC parts cost premium.

Five-year view (fleet-wide):

- Fuel: Option A saves ~$68M cumulative; Option B saves ~$196M (at $90/bbl equivalent, normalized).

- Compliance headroom: Option A hits NOx goals at most hubs; Option B cruises through and unlocks quieter slot categories at two curfewed airports.

- Operational risk: Option A minimal; Option B requires a sharper line-station maturity plan (CMC spares, gearbox LRU handling, borescope criteria).

My take: If cash is tight and your Stage length is short, A-first can be smart triage. If your network touches fee-tight Europe or curfewed hubs, B pays you twice and keeps finance from sweating the ESG line on earnings calls.

Where the sand traps are (lessons I wish I’d learned earlier)

- Combustion stability vs. NOx. Lean it out too far without the right staging/sensors and you’ll chase rumble and flameouts. The fix is fuel pre-mix quality, swirl patterning, and control logic—not just “add a degree” on the schedule.

- Thermal margin accounting. CMCs give you temperature headroom, not a license to raid cooling air recklessly. I’ve seen teams steal too much cooling for cycle points and hand the problem to blade life and tip clearances later.

- Integration drag. An open-rotor can ace SFC on a dyno and give it back in pylon/airframe penalties. Put the airframer in the room early; installation is half the game.

- Maintenance realism. New materials and processes demand new NDI and repair schemes. If your MRO can’t scale thermography and laser-shock-peen rework, your shop days get long and your AOGs loud.

- Certification pacing. Regulators are comfortable with the concepts; they’re still writing fine print on noise/NOx metrics, durability, and hydrogen/SAF variability. Don’t count test chickens before the last corner case passes.

- For operator-friendly explainers that connect combustor/turbomachinery choices to fuel, fees, and slots, start with our in-house series Sustainable Engine Technologies. If you want the near-term airframe side that pairs especially well with cleaner engines, Airbus’s Extra Performance Wing program is a good window into morphing surfaces and load control: Airbus—Extra Performance Wing.

How hydrogen and SAF change the playbook (but not the fundamentals)

Hydrogen flames burn fast and can spike NOx if you treat them like Jet-A. The answer is premixing, staged injection, and possibly dilution air to keep temps in check. SAFs, for their part, often have lower aromatics and different sooting behavior; lean-burn combustors usually love that, but ignition and low-power stability can shift. The through-line: low-NOx combustors stay the right answer, you just tune injection, mixing, and control to the fuel.

What airlines can—and should—do in 2025–2027

- Run a two-track business case. Price a combustor upgrade on current engines and a next-gen induction on lease rollovers. Model fees, fuel, and slot access (noise) explicitly.

- Build your shop capability. If CMCs and lean-burn dynamics are in your future, upskill NDI now; get your borescope criteria and on-condition limits aligned with the OEM.

- Instrument reality. Stream the right EHM: exhaust gas spreads, dynamics flags, start margins, CMC wear indicators. Data pays back in longer time-on-wing and fewer surprises.

- Align with sustainability finance. Tie your upgrade/induction plan to CO₂ and NOx trajectories; capital likes a clean line from tech to compliance to lower cash burn.

If you want a curated set of explainers that connect combustor tech to fleet decisions, we keep a running series in Sustainable Engine Technologies. For concepts that are about to leave the lab (open-rotor integration, morphing nozzles, ultra-high AR wings paired with hotter cores), our Experimental & Future Aircraft hub is the rabbit hole you want. And when rules shift (CAEP updates, local NOx fees, test-protocol tweaks), we summarize the change and the “so what” in Regulatory Updates so your slide decks stay current.

A day in the rig: a short, fictional case study from the combustor cell

We were chasing a stubborn low-power rumble on a lean-burn rig. The dynamics looked like textbook 1–2 kHz content riding a long-idle spool-down. The team’s first instinct was to fatten the pilot. We tried that; NOx crept up and the rumble only moved. A younger combustion engineer suggested a swirler vane tweak and a fuel-split schedule change that raised prevaporizer residence time by a few milliseconds at that idle point. The next run, the spectrum flattened; the flame anchoring stabilized; and NOx stayed flat. Two weeks later, the same tweaks went into the engine test, and the FADEC table got a new corner-case gate. That’s what “breakthrough” looks like in real life—small geometry and schedule changes that quiet the bad physics without crushing the good.

FAQs I keep getting from flight departments and CFOs

Will low-NOx combustors hurt relight or cold soak performance? Not if you treat ignition as a first-class requirement. Modern systems use pilot stabilization and smart fuel splits to keep starts and altitude relights robust. Test it mercilessly.

Are CMCs worth the hassle? If you’re chasing higher TIT and lower cooling flows, yes. They carry a parts-cost premium today, but the time-on-wing gains and SFC improvements are hard to find elsewhere.

Does open-rotor make schedule sense? Depends on your Mach and routes. On 0.75–0.78 cruise and mid-length legs, the fuel math is compelling. On long, high-Mach sectors, the integration trade winds shift. Airframe partners decide half this story.

Can SAF alone give me the 2030 win? SAF is essential for lifecycle CO₂, but the cash fuel you burn is the fuel you pay for. Turbomachinery + low-NOx cut that baseline, then SAF multiplies the climate benefit.

What success looks like on your ops dashboard in 2030

- Block fuel down 15–20% on your bread-and-butter legs.

- NOx margins so comfortable that fee tables and cert renewal don’t spike blood pressure.

- Shop visits longer apart and shorter when they happen—because you planned spares, NDI, and training.

- Noise profiles that let you claw back dawn/dusk slots at curfewed hubs.

- A slide your CFO likes: fuel cash out down; compliance risk down; ESG score up.

Certification: performance-based paths help

Expect certification to focus on durability, dynamics, and corner-case operability as much as steady-state emissions. The FAA’s performance-based approach in Part 23 reform is a good bellwether for how novel materials and control laws get approved when the means-of-compliance story is solid: FAA—Part 23 Performance-Based Standards (Final Rule PDF).

The bottom line (what I tell boards and base chiefs)

By 2030, the winning propulsion stack is low-NOx combustors paired with hotter, smarter turbomachinery—geared where it pays, CMC-stiffened where it counts, and software-steady everywhere flames touch metal (or ceramic). Expect up to ~25% less fuel versus 2020 baselines and as much as ~80% less NOx against legacy limits—without waiting for a new fuel to save you. That buys airlines cash relief now, regulatory headroom later, and a cleaner bridge to hydrogen and hybrid-electric systems as they mature.