Introduction: From Steam Gauges to Flying Servers

Step inside the flight deck of a 1970s Piper Cherokee, and you are met with a mechanical world of cables, pulleys, and analog steam gauges. Now, step onto the flight deck of a Boeing 787 Dreamliner or a Gulfstream G650. You aren’t just in a plane; you are inside a flying supercomputer processing terabytes of data per second.

As the US aviation industry shifts from mechanical systems to digital networks, a critical labor shortage has emerged. We don’t just need mechanics who can turn wrenches; we need experts who can keep the electrons flowing. Enter the Avionics Technician.

While the traditional A&P Mechanic ensures the wings stay on, the Avionics Technician (affectionately known in the hangar as “Sparky”) maintains the aircraft’s central nervous system—the weather radar, the autopilot, and the complex glass cockpit arrays. If you prefer logic puzzles, clean working environments, and high-tech troubleshooting over hydraulic fluid and grease, pursuing avionics technician training could be your smartest career move.

In this comprehensive guide, we will untangle the web of licenses (FCC, NCATT, FAA), map out your training options, and show you how to launch a lucrative, future-proof career.

Part 1: What Does an Avionics Technician Actually do?

“Avionics” is simply a shorthand for Aviation Electronics. However, the job is far more complex than just changing fuses or swapping lightbulbs.

An Avionics Technician is responsible for the installation, troubleshooting, and repair of every electronic system on the airframe. Modern avionics technician training covers five core pillars required for FAA NextGen Airspace compliance:

- Communication (Comms): Maintaining VHF/HF radios and SATCOM (Satellite Communications) systems that keep pilots connected to ATC over the ocean.

- Navigation (Nav): Calibrating GPS/WAAS, VOR, Instrument Landing Systems (ILS), and Laser Inertial Reference Systems (IRS).

- Surveillance: Ensuring Weather Radar, Transponders (ADS-B Out), and Traffic Collision Avoidance Systems (TCAS) are “seeing” the world correctly.

- Auto-Flight: Troubleshooting Autopilots and Flight Management Systems (FMS) that fly the aircraft from takeoff to touchdown.

- In-Flight Entertainment (IFE): In the commercial airline world (Part 121), a broken Wi-Fi router or seatback screen can cause as many customer complaints as a delayed flight.

Because a single bent pin in a cannon plug can ground a $100 million jet, this career demands extreme precision.

Part 2: The “License” Web (FAA, FCC, and NCATT)

Unlike the structural side of aviation, where one license rules them all, avionics is fragmented. Understanding these certifications is the first step in your training journey.

1. The FCC GROL (The Federal Requirement)

The Federal Communications Commission (FCC) owns the airwaves. To legally fix or adjust internal circuitry on radio transmitting equipment (like radar or VHF radios), you must hold the General Radiotelephone Operator License (GROL).

- Is it mandatory? Legally, only for transmitters. However, practically every major airline (United, Delta, American) and Repair Station requires it as a prerequisite for hiring.

- The Exam: You must pass Element 1 (Marine Law), Element 3 (General Theory), and preferably Element 8 (Radar Endorsement).

2. The NCATT AET (The Industry Standard)

Managed by ASTM International, the Aircraft Electronics Technician (AET) certification has become the gold standard for modern competency.

- The Shift: While the FCC covers old-school analog radio theory, the NCATT AET focuses on modern digital logic, ESD (Electro-Static Discharge) safety, and data bus systems (ARINC 429). It is increasingly preferred by employers for “glass cockpit” aircraft.

3. The FAA A&P License (The Power Move)

Can you work in avionics with just an A&P license? Yes. In fact, under 14 CFR Part 65, an Airframe-rated mechanic can perform almost all avionics installation work (routing wire, mounting boxes). The most highly paid technicians in the US are often “Hybrids”—those who possess both their FCC/NCATT avionics certifications and their A&P license.

Part 3: Pathways to Avionics Technician Training

How do you learn to troubleshoot a wiring fault buried deep in a fuselage? You have three main paths.

Pathway A: Part 147 Technical Colleges

Many FAA-approved Part 147 schools now offer dedicated avionics technician training tracks alongside their maintenance programs.

- Curriculum: Deep dives into DC/AC theory, solid-state electronics, digital logic, and troubleshooting.

- Duration: 12 to 18 months.

- Pros: You graduate prepared for the FCC GROL and NCATT exams, often with hands-on experience on real test benches.

Pathway B: Military Service (The “Joint Service” Route)

The US military flies the most advanced hardware on the planet. Enlisting as an avionics specialist in the Air Force or Navy is arguably the best training available.

- The Advantage: You get paid to learn on cutting-edge jamming, radar, and weapons systems.

- The Transition: Upon discharge, your experience is documented on your Joint Services Transcript (JST), allowing you to test for civilian certifications immediately or qualify for the FAA Mechanics exam based on experience.

Pathway C: On-the-Job Training (OJT)

You can enter the field as a helper or “wire puller” at a Part 145 Repair Station.

- The Reality: You will likely spend your first year removing interior panels and routing wire bundles.

- The Trade-off: While you earn money immediately, learning the complex electronic theory required for troubleshooting is much harder without formal classroom training.

Part 4: The Skillset – It’s Not Just Plugging In Cables

Passing the test is one thing; doing the job is another. Successful avionics technician training builds specific, high-dexterity skills.

1. Precision Soldering & Crimping

Avionics is delicate. You must learn to solder to IPC J-STD-001 standards. A “cold solder joint” looks fine to the naked eye but will crack under vibration, causing intermittent failures that are nightmares to track down. Equally important is crimping—using calibrated tools (like Daniels DMC) to attach pins to wires. A bad crimp means a bad signal.

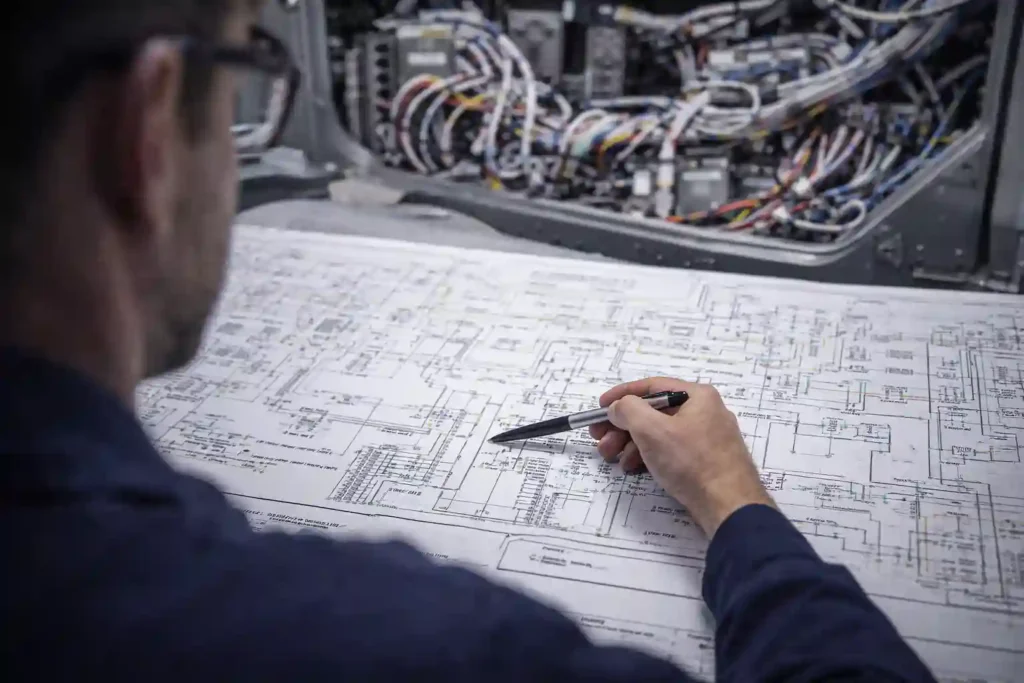

2. Schematic Literacy

An avionics tech doesn’t read a manual; they read a map. You must be able to look at a wiring diagram schematic that spans 50 pages and trace a single signal wire from a cockpit switch, through three bulkheads, to a servo in the tail.

3. Software Management

On a modern Airbus A350, “repairing” a part often means updating its software. You must be comfortable using data loaders and managing complex configuration files.

Part 5: Essential Tools for the “Sparky”

If you are entering avionics technician training, your toolbox will look very different from a general mechanic’s. You don’t need heavy hammers; you need precision instruments.

- The Multimeter: This is your primary diagnostic tool. You need a high-quality, True-RMS meter to measure voltage, current, and resistance accurately.

- Wire Strippers: Precision strippers that cut insulation without nicking the copper strands are mandatory.

- Terminal Picks: Tiny tools used to unlock and de-pin connectors.

- Crimpers: Specialized (and expensive) pliers used to attach pins to wires.

For a full breakdown of the specific meters and crimpers used by pros, check out our Ultimate Aircraft Mechanic Tool List.

Part 6: Salary and Career Outlook

Is the investment in avionics technician training worth it? Absolutely.

Because modern aircraft are increasingly dependent on electronics, the demand for avionics techs is outpacing the demand for structural mechanics.

- Entry Level: $25 – $32 per hour.

- Experienced (5+ years): $40 – $55 per hour.

- Master Technician: $60+ per hour ($125k+ annually).

Where can you work?

- Commercial Airlines: Focusing on overnight maintenance of navigation and entertainment systems.

- General Aviation: Upgrading older Cessnas with new Garmin “Glass Cockpits.”

- Space & Defense: Companies like SpaceX and Blue Origin recruit avionics techs aggressively for rocket assembly.

Part 7: The Future – eVTOL and NextGen

The future of aviation is electric.

eVTOL (Electric Vertical Take-Off and Landing) aircraft are essentially flying batteries controlled by software. They have no pistons and no hydraulics. They are 100% avionics.

Technicians undergoing avionics technician training today are positioning themselves to lead the “Urban Air Mobility” revolution. While traditional mechanics may struggle to adapt to electric engines, the avionics tech is already fluent in the language of volts, amps, and logic gates.

Summary: Your Circuit to Success

If you are ready to trade the grease for the multimeter, here is your roadmap:

- Get Educated: Enroll in a formal avionics technician training program.

- Get Certified: Prioritize the FCC GROL and NCATT AET.

- Buy Quality Tools: Invest in a professional multimeter early.

- Expand Your Skills: Consider cross-training. Understanding how to inspect airframes using Non-Destructive Testing methods will make you an even better troubleshooter.

The cockpit is getting smarter. The industry needs technicians who are smarter, too.

Frequently Asked Questions (FAQ)

Do I need to be good at math to be an Avionics Technician?

You don’t need to be a mathematician, but you do need a solid grasp of Algebra and Physics. You will use Ohm’s Law ($V = I \times R$) daily to calculate loads. If you can solve basic equations and understand logic, you will succeed.

Can I be an avionics tech if I am colorblind?

Generally, no. Aircraft wiring is color-coded (e.g., a white wire with a blue stripe), and resistor values are marked with colored bands. If you cannot distinguish between red, green, and amber, you will likely be disqualified from safety-critical avionics roles.

What is the difference between “Line” and “Bench” maintenance?

- Line Maintenance: You work on the aircraft itself. You troubleshoot the system, swap out the “black box,” and get the plane flying.

- Bench Maintenance: You sit in a shop. The “black box” is brought to you, and you open it up to repair the microscopic circuit boards inside.

- Note: Most avionics technician training covers both, but Line Maintenance is the most common entry point.

Does an A&P license cover avionics?

Technically, yes. An A&P mechanic is legally allowed to perform avionics work. However, they typically lack the specialized training to troubleshoot complex digital systems effectively, which is why specialist avionics techs are so valued.