Introduction: The “Eyes” of the Mechanic

Twenty years ago, if an engine had low compression or made a strange noise, you had one option: tear it down. That meant removing cylinders, costing thousands of dollars in labor and downtime. Today, we have a cheat code.

The borescope (or videoscope) is the single most money-saving tool in the Aviation Maintenance Technician’s arsenal. It allows you to inspect valves, pistons, and turbine blades without removing a single screw.

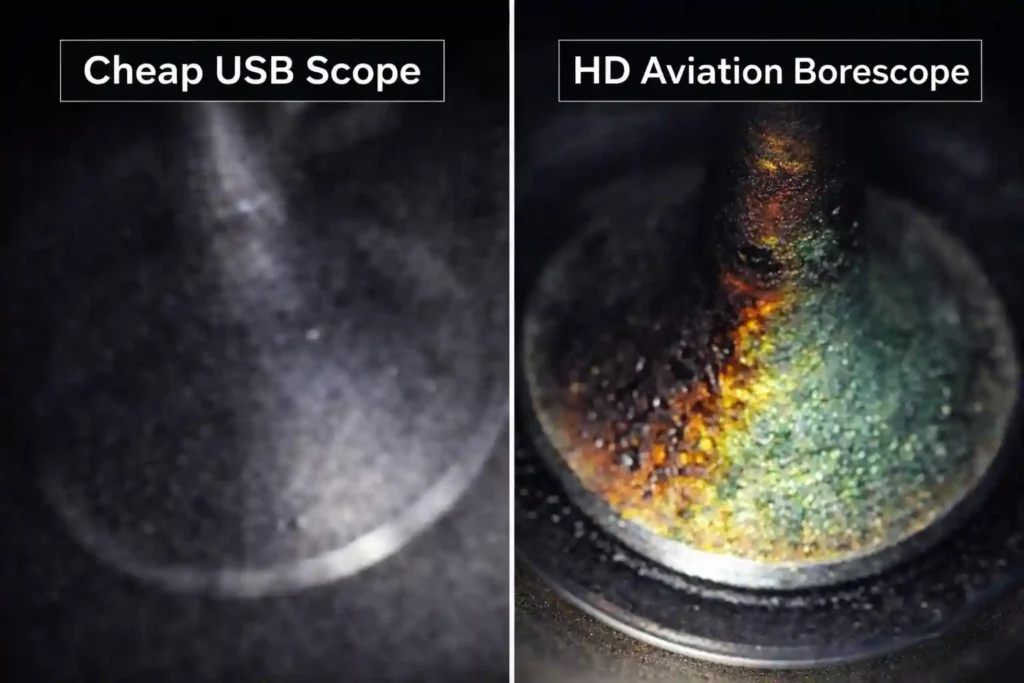

However, the market is flooded with cheap plumbing cameras that are useless for aviation. An aircraft engine is not a kitchen sink. It requires high resolution, specific focal lengths, and, most importantly, articulation.

In this guide, we break down the best aviation borescopes for 2025, categorized by budget and use case. Whether you are a student, a General Aviation (GA) owner, or a commercial inspector, here is the gear you need to see the invisible.

Buying Criteria: What Makes an “Aviation” Scope?

Before you spend money, you must understand the physics of the inspection. A $30 USB plumbing camera from Amazon is designed to look down a straight, wide drainpipe. An aircraft engine is a cramped, dark, and complex mechanical maze. Here is why the cheap cameras fail in the hangar.

1. Articulation (The Dealbreaker)

This is the single most critical feature. If the probe cannot bend on command, it is useless for cylinder inspections.

- The “J-Turn” Requirement: To inspect an exhaust valve—the most critical failure point in piston engines—the camera must enter the spark plug hole, travel to the center of the cylinder, and then turn 180 degrees backward to look up at the valve face.

- Rigid vs. Articulating: A straight or rigid probe can only see the piston top and the cylinder walls. It will leave you completely blind to the valves, which is exactly where 90% of failures occur.

- Two-Way vs. Four-Way: For most mechanics, “Two-Way” articulation (bending Left/Right) is sufficient because you can rotate the handle to see Up/Down. “Four-Way” (joystick control) is a luxury, but not strictly necessary for general aviation.

2. Probe Diameter & Tolerance

Size matters, but not for the reason you think. It is not just about fitting through the hole; it is about getting stuck.

- Piston Engines (Lycoming/Continental): A 5.5mm to 6.0mm probe is the industry standard. While spark plug holes are 14mm or 18mm, you need space to maneuver.

- Turbine Engines (PT6, CFM56): These engines have dedicated borescope ports that are incredibly narrow. A 3.9mm or 4.0mm probe is often required.

- The Carbon Factor: Never buy a probe that “just barely” fits. Old cylinders often have heavy carbon buildup on the threads, narrowing the opening. A probe with zero clearance can easily become trapped.

3. Depth of Field (The “Macro” Focus)

This is where 99% of generic cameras fail.

- Plumbing vs. Aviation: A plumbing camera has a focal point set to “Infinity” or 1 meter, allowing it to see far down a pipe. An aviation scope needs a Macro Lens with a focal range of 10mm to 30mm.

- The Reality: Inside a cylinder, the wall is less than an inch from the lens. If you use a plumbing camera, the wall will be a blurry, unrecognizable blob. You need a lens designed for “Near Focus” to spot hairline cracks or cross-hatching patterns.

4. Probe Stiffness (Rigidity)

This is the “hidden” feature nobody talks about.

Semi-Rigid Interlocking: A proper aviation probe uses a “semi-rigid” or “gooseneck” metal cable. When you push it straight out, it holds its shape in mid-air, allowing you to position the camera exactly in the center of the combustion chamber without touching the oily walls.

The “Wet Noodle” Problem: Cheap USB cables are soft. When you push them horizontally into a cylinder, they immediately droop and lay on the oily piston.

Category 1: The “Student” & DIY Owner (Under $250)

If you are an A&P student building your first toolkit, or a pilot-owner performing “Preventive Maintenance” (under FAR Part 43 Appendix A), you do not need to mortgage your house for a borescope. The smartest move in 2026 is to leverage the powerful computer you already have in your pocket: your smartphone.

Top Pick: Teslong / Vividia (Smartphone Articulating Series) These devices are essentially high-end probes that lack a screen and battery. Instead, they plug directly into your iPhone (Lightning or USB-C) or Android device via a dedicated app.

- Why It Wins:

- Screen Quality: Manufacturers of industrial tools cannot compete with Apple or Samsung. Your phone’s OLED Retina display is brighter, has better contrast, and higher resolution than the screen on a $5,000 industrial videoscope. This makes identifying subtle corrosion or valve burning much easier.

- Portability: The entire unit coils up small enough to fit in a cargo pocket or a side pouch of your backpack.

- Price-to-Performance: Because you aren’t paying for a screen, battery, or processor, 100% of your money goes into the camera optics and the articulation mechanism.

- Key Specs:

- Resolution: True 1080p HD (High Definition).

- Articulation: 2-way (Left/Right) with a range of up to 210°, allowing you to easily look back at the valve seats.

- Probe Diameter: Typically 6.0mm or 8.5mm options.

- The Trade-off:

- Battery Drain: It draws power from your phone. A 20-minute inspection can drain 15-20% of your battery.

- The “Oil Factor”: You are bringing your personal $1,000 phone into a dirty environment. If you drop your phone in a puddle of Skydrol or oil, it’s an expensive mistake.

Category 2: The “Prosumer” Mechanic ($400 – $900)

This category represents the “Sweet Spot” for the vast majority of working mechanics. If you are inspecting Lycoming, Continental, or Rotax engines daily, you need a standalone tool that is rugged, reliable, and ready to work the second you pick it up.

Top Pick: Teslong TD500 / Oasis Scientific Vividia These are all-in-one handheld units featuring a pistol-grip design, an integrated high-definition screen, and ruggedized housing.

- Why It Wins:

- “Grab and Go” Reliability: There is no Bluetooth pairing, no app crashes, and no need to remove your phone case. You simply press the power button, and you are inspecting in 3 seconds.

- Durability: Unlike the USB cables in the student category, these probes typically feature Tungsten-braided sheathing. This metal mesh protects the cable from sharp cylinder fins and rough handling, significantly extending the tool’s lifespan.

- Ergonomics: The pistol grip allows you to hold the screen, steer the probe, and snap photos all with one hand, leaving your other hand free to turn the propeller or adjust lighting.

- Key Specs:

- Probe: 5.5mm diameter (fits tight spaces better than the 6.0mm smartphone units).

- Battery: Dedicated rechargeable lithium-ion battery providing 4+ hours of continuous run time.

- Storage: Images and 1080p video are saved directly to a removable Micro-SD card, making it easy to transfer reports to your computer or customer records.

- Verdict: For the professional General Aviation mechanic, this tool offers 95% of the capability of a high-end unit at 10% of the cost. It is the best value-for-money tool on the market today.

Category 3: The Commercial Professional ($1,500 – $20,000)

When you move into Part 145 Repair Stations, heavy turbine maintenance (Pratt & Whitney, GE, Rolls-Royce), or legally mandated NDT inspections, “good enough” is no longer acceptable. You need certified equipment with measurement capabilities.

Top Pick: Waygate Technologies (formerly GE Inspection) / Olympus (IPLEX Series) These are the heavyweights of the industry. They are not just cameras; they are precision measurement instruments found in the maintenance manuals of major airlines.

- Why It Wins:

- Stereo Measurement: This is the killer feature. If you find a crack on a turbine blade, you don’t just guess its size. You use cursors on the screen to measure the length, width, and depth of the defect with accuracy down to the millimeter. This data determines if an engine stays on wing or requires a $100,000 overhaul.

- Image Processing: They utilize advanced CCD sensors and proprietary image algorithms (like WiDER or HDR) to see clearly in the high-contrast environment of a jet engine, cutting through glare and brightening dark corners simultaneously.

- Interchangeability: You can swap probes (different lengths and diameters) on the same base unit.

- The Cost:

- These units are prohibitively expensive for individuals. However, for an MRO facility, the cost is justified by the ability to perform “On-Wing” measurements that save millions in unnecessary engine removals.

How to Use Your Scope (Safely)

Buying the best aviation borescope is useless if you destroy it on the first day. Here are three rules for longevity.

1. Cool Engine Only

Never insert a borescope into a hot cylinder.

- The Risk: Most camera sensors begin to fail at 140°F (60°C). If you stick a probe into a cylinder immediately after shutdown, the heat will melt the plastic lens coating and fry the sensor. Wait until the cylinder head is cool to the touch.

2. Uncurl Before Removing

This is the rookie mistake. You articulate the tip 180° to look at the valves. Then, you try to pull the probe out of the spark plug hole without straightening it.

- The Result: You hook the curled tip on the spark plug threads and rip the control cables. Always hit the “Reset” or “Straighten” button before withdrawing.

3. Clean with Alcohol

Gasoline and oil residue will cloud the lens. Use a cotton swab dipped in Isopropyl Alcohol to gently clean the lens tip after every use. Do not use brake cleaner, which can melt the epoxy seals.

Understanding What You See

Owning the tool is step one. Interpreting the image is step two.

- Valves: You are looking for asymmetrical color patterns. A healthy exhaust valve has a bullseye pattern. An edge that looks green or pizza-slice shaped indicates a “hot spot” or leakage.

- Cylinders: You are looking for “cross-hatching” (good) vs. vertical scoring or scuffing (bad).

- For a deep dive on interpretation, read our full Borescope Inspection Guide in the NDT Insights category.

Conclusion: The ROI of Vision

The return on investment (ROI) of a quality borescope is immediate. Finding one cracked cylinder before you buy an airplane, or saving a customer a teardown by confirming a valve is healthy, pays for the tool instantly.

For the modern technician, the question is not “Can I afford a borescope?” It is “Can I afford not to have one?” Whether you choose a $250 smartphone attachment or a $25,000 measurement system, ensuring you have the ability to inspect the internal health of your engine is paramount to safety.

Frequently Asked Questions (FAQ)

1. Can I use a medical endoscope for aviation? No. Medical scopes are designed for the human body (wet, dark, squishy). They are often too flexible and lack the rigidity to be pushed into an engine cylinder. Also, used medical equipment can carry biohazards. Stick to industrial aviation mechanic tools.

2. What is the difference between WiFi and Screen units? WiFi units use your phone as the display. They are cheaper and have great screens (your phone) but suffer from lag and battery drain. Dedicated screen units are lag-free, rugged, and start up instantly, which professionals prefer.

3. Do I need a dual-lens probe? A dual-lens probe has a camera on the front and a camera on the side. This eliminates the need to use a screw-on side-view mirror. It is a fantastic feature for inspecting cylinder walls and eliminates the risk of a mirror falling off inside the engine (a massive FOD risk).

4. How often should I borescope my engine? For General Aviation, it is recommended at every 100-hour or Annual inspection. For turbine engines, manufacturers like Pratt & Whitney specify intervals in the maintenance manual, often every 400–600 hours.

5. Is a 3.9mm probe better than a 5.5mm? Not necessarily. A smaller probe allows access to tighter spaces (like turbine igniter holes), but generally, a larger lens (5.5mm or 6.0mm) allows for a larger sensor and better lighting. Use the largest probe that fits comfortably in your application.